The steel structure office building is a standard product in the context of urban modernization development. It focuses on the rational development and utilization of urban functional regional space, which is the fundamental expression of modern multi-functional defined space. The structure of office buildings requires new composite materials and stricter restrictions on construction technology. For example, the steel building office building as a representative of the new building type is a breakthrough in the innovative development of traditional brick and concrete buildings. The emergence of steel construction in high-rise office buildings has more specialized requirements for building structure design, floor height restrictions, and selection of construction components. Office buildings generally concentrated in the center of the city or prosperous locations, so the surrounding environment will also restrict the construction of office buildings.

Product Parameters

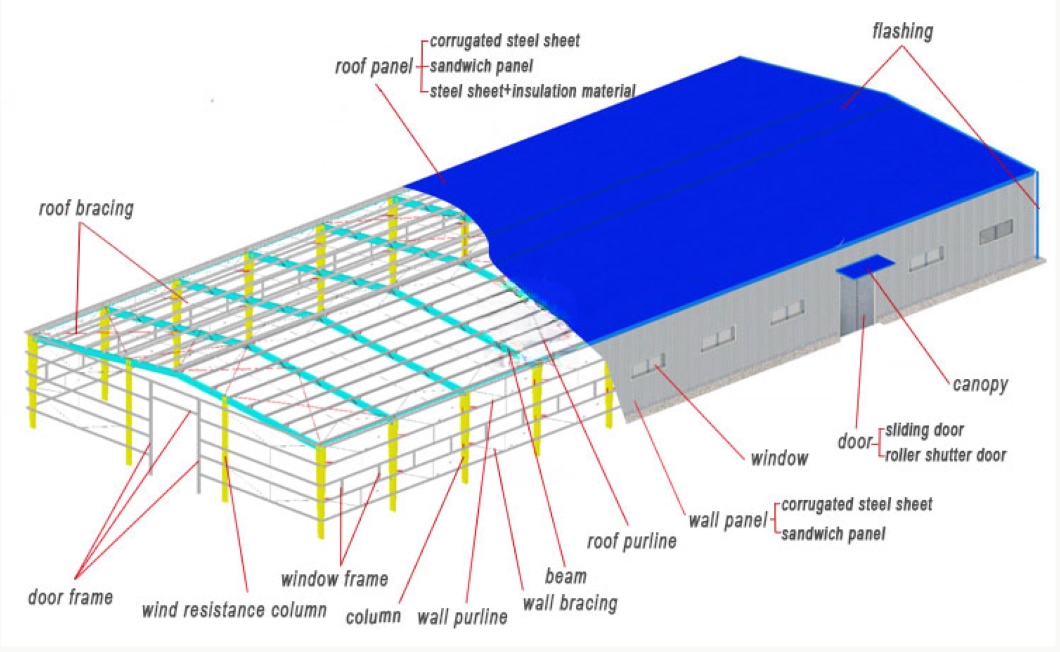

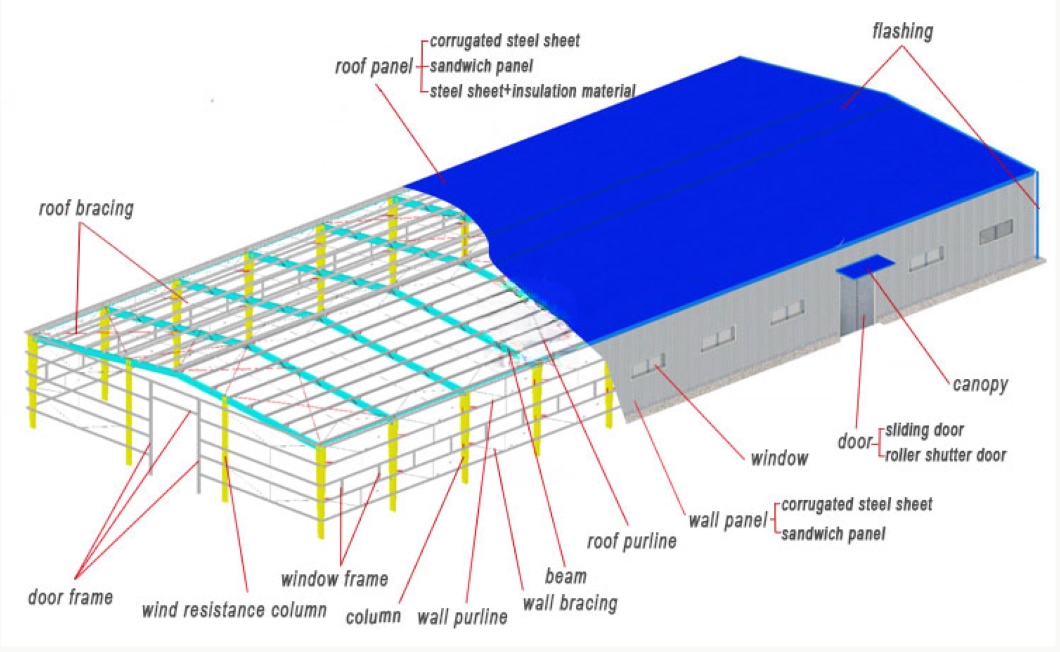

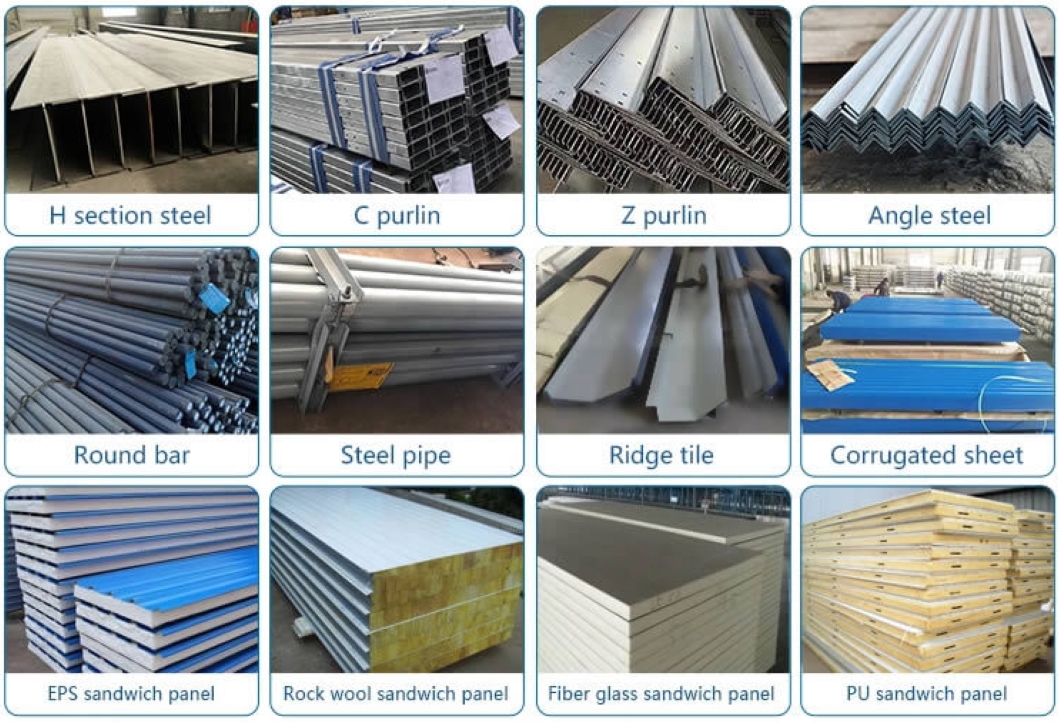

Main Steel Frame

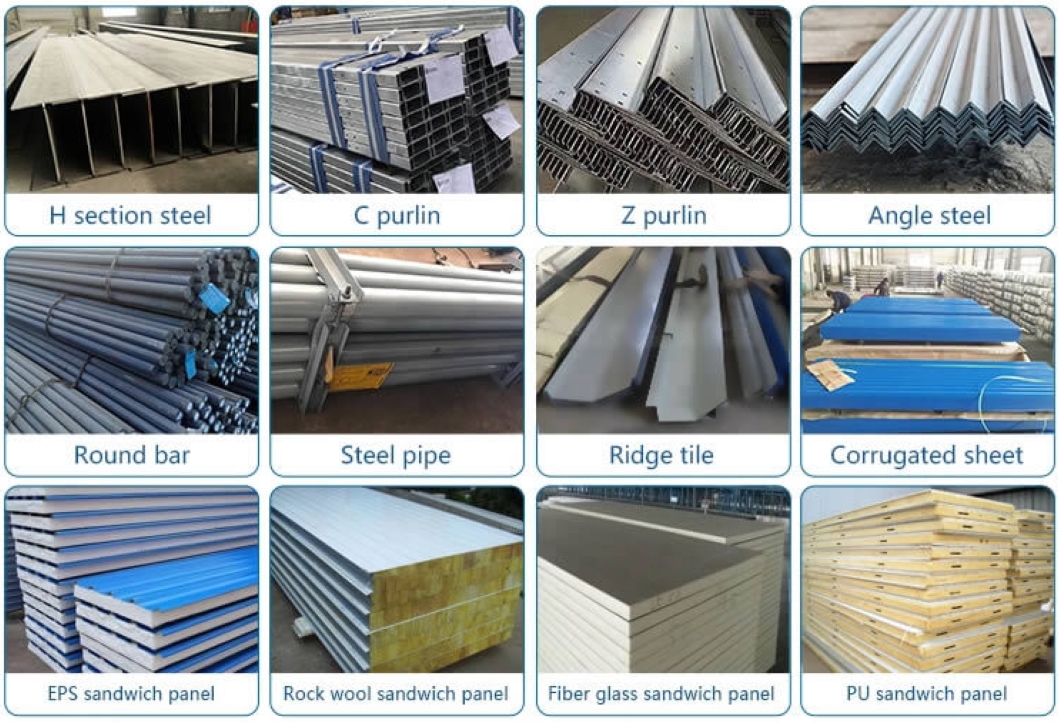

| H section steel | Q235/Q355 grade steel 8mm/10mm |

Welding | Automatic submerged arc welding |

Rust removal | Shot blasting Sa 2.5 |

Surface processing | Alkyd painting or galvanized |

Intensive bolt | Grade 10.9 |

Sub Steel Frame

| Angle brace | L50x4, Steel Q235, processed and painted |

Cross support | Φ20, Steel Q235, processed and painted |

Tie rod | Φ89*3, Steel Q235, processed and painted |

Bracing | Φ12, Steel Q235, processed and painted |

Standard bolt | Galvanized bolt |

Roof

| Purlin | C#160,C#180,C#250, galvanized |

Roof panel | Insulated sandwich panel or corrugated steel plate |

Skylight panel | 2.0mm FRP |

Accessories | Glass cement, self-tapping screws,etc |

Flashing/Trimming | Sheet steel profile |

Gutter | Galvanized sheet steel profile |

Water pipe | Φ110 PVC |

Walls

| Purlin | C#160,C#180,C#250, galvanized |

Wall | Insulated sandwich panel or corrugated steel plate |

Accessories | Glass cement, self-tapping screws,etc |

Flashing/Trimming | Sheet steel profile |

Ventilation | Axial fan |

Doors | Rolling door/sliding door | Automatic or manual |

Windows | Sliding/fixed/shutter | Aluminum or PVC window frame |

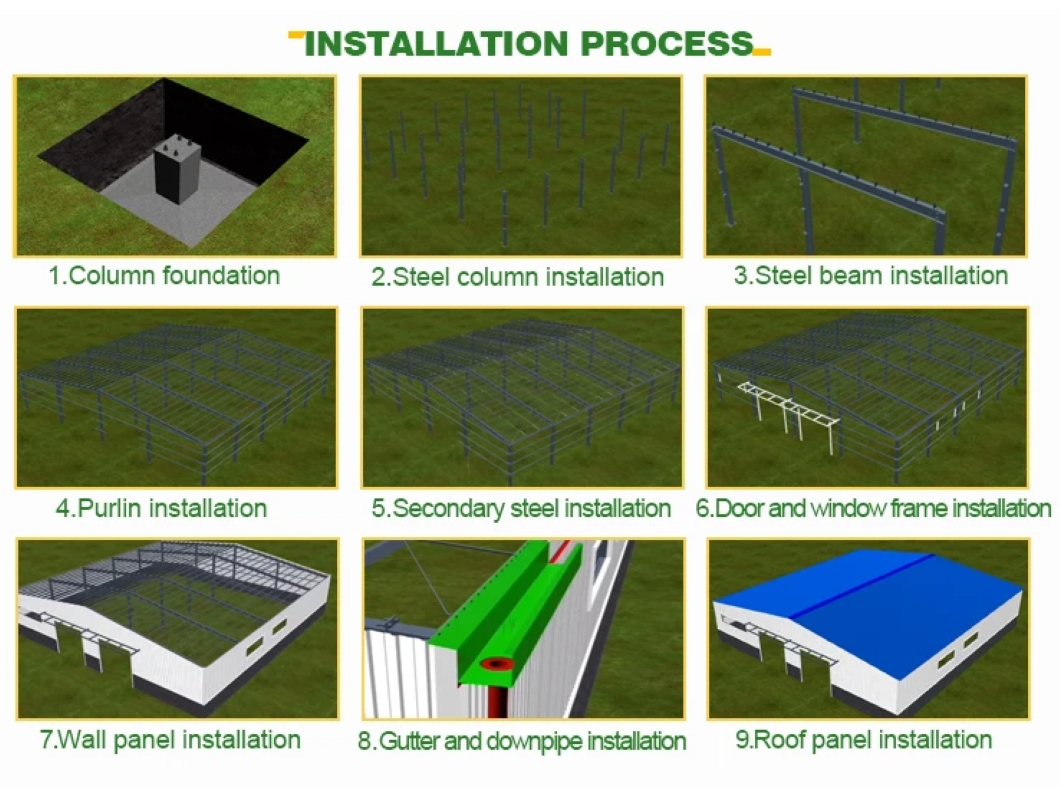

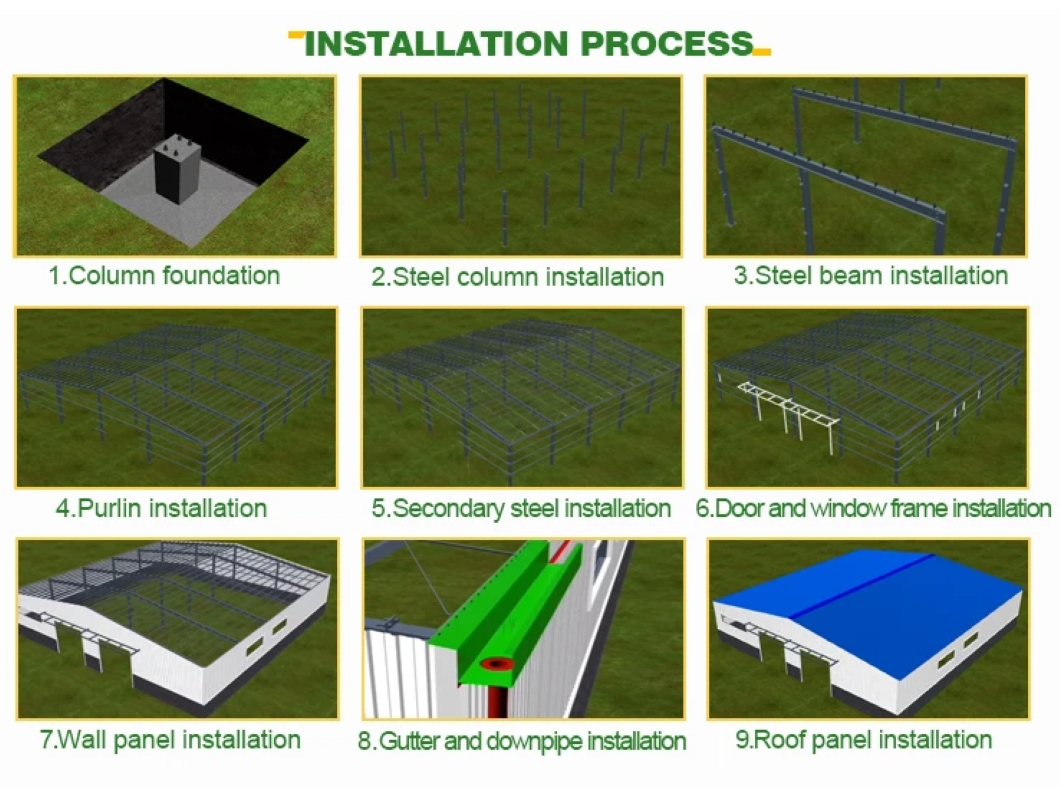

Product Installation

With our top-notch installation support, you can rest assured that setting up your workshop will be a breeze. We provide detailed installation drawings and videos to guide you every step of the way. And if you need extra assistance, our dedicated staff and engineers are ready to be on-site to personally guide you through the process.

But that's not all! Our products are designed with convenience in mind. Loading and unloading them is a piece of cake. You can easily use a crane at the destination, and with just two people, you can unload the entire workshop in under half an hour. And don't worry about damaging the packaging - we guarantee it will remain intact!

When it comes to quality, we don't compromise. Our Customized Modern Space Frame Building Prefab Steel Structure Workshop is built to last. With a 50-year warranty and lifelong responsibility for after-sales service, you can trust that you're investing in a product that will stand the test of time.

Contact us for design

We have professional designers who can provide you with free design solutions according to your requirements. So, if you have any needs, you can contact us at any time.

Please kindly inform us of the information below if you are interested in our products.

1. Project Progress: Is Land Purchased? Is it licensed by the government?

2. Usage: for warehouse, workshop, showroom, etc.

3. Location: In which country will it be built?

4. Local Climate: Wind speed, Snow load (max. Wind speed)

5. Design: Please provide the design drawing. Or do you need us to design for you?

6. Dimension: Length*width*height

7. Crane Beam: Do you need crane beam inside the steel structure?

8. Roof and Wall: determine the panel material, such as color steel panel, and metal sandwich panel.

9. Windows and Doors: what material, quantity, and type?