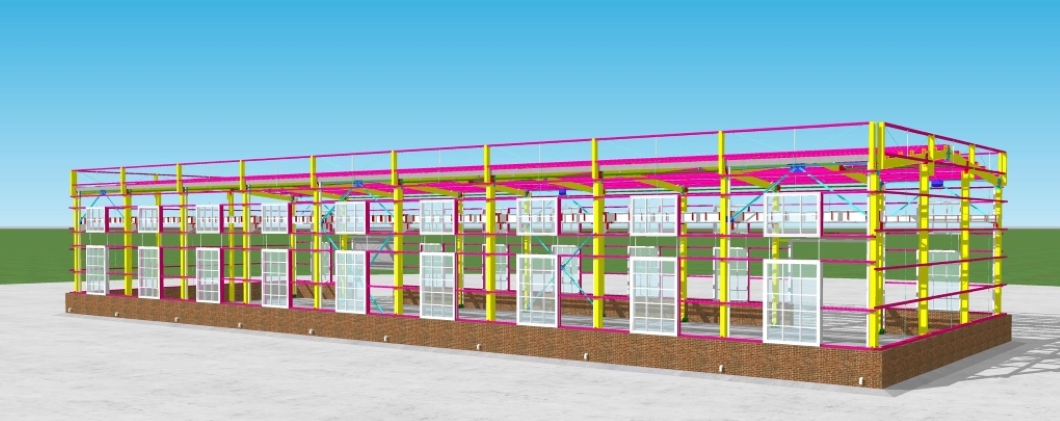

The steel structure office building is a multi-layer steel structure building, improving the space utilization rate and obtaining a more extensive space usage area in a smaller construction site. The steel structure office building is light in weight and easy to transport. The components are prefabricated in the factory and then delivered to the site. The precision is high, and the quality is controllable. In addition, the steel structure office building has been industrialized, which can significantly promote the construction speed of the building, reduce the construction cost, have strong anti-corrosion ability, and simple maintenance in the later stage.

Product Features

1. The strength of Steel Frame Buildings is higher than traditional brick and concrete structures. Steel structure buildings are also much stronger than a traditional wood structures. So, it can build more structures higher than traditional building materials.

2. Steel Frame Buildings perform better earthquake resistance than traditional building materials such as brick concrete structures and wood structures. Because it has better flexibility. So, if want to build a high-level building, using a steel structure build is a good idea because it can resist earthquakes.

3. Steel metal building are easily customizable in their appearance and can be designed to fit a certain local or a specific company brand. From eaves to massive garage doors to skylights, we can make sure that your building has the look pictured in your head.

The advantage and disadvantage of Steel Structure:

Due to the excellent plasticity and toughness of the steel, it can have large deformation and can bear the dynamic load well. Secondly, the steel has good homogeneity and isotropy. It is an ideal elastomer and is most consistent with the underlying assumptions of general engineering mechanics. Therefore, the steel structure seismic performance is better than that of reinforced concrete structures.

The steel structure has a low self-weight and low stiffness, so when calculating the horizontal earthquake action, the seismic force is often smaller than the concrete structure, and its plasticity is strong. It can absorb a lot of energy during an earthquake, so the steel structure is better. Still, the steel structure is too soft, comfortable with producing massive horizontal displacement, and inadequate fire performance, these are inferior to concrete structures.

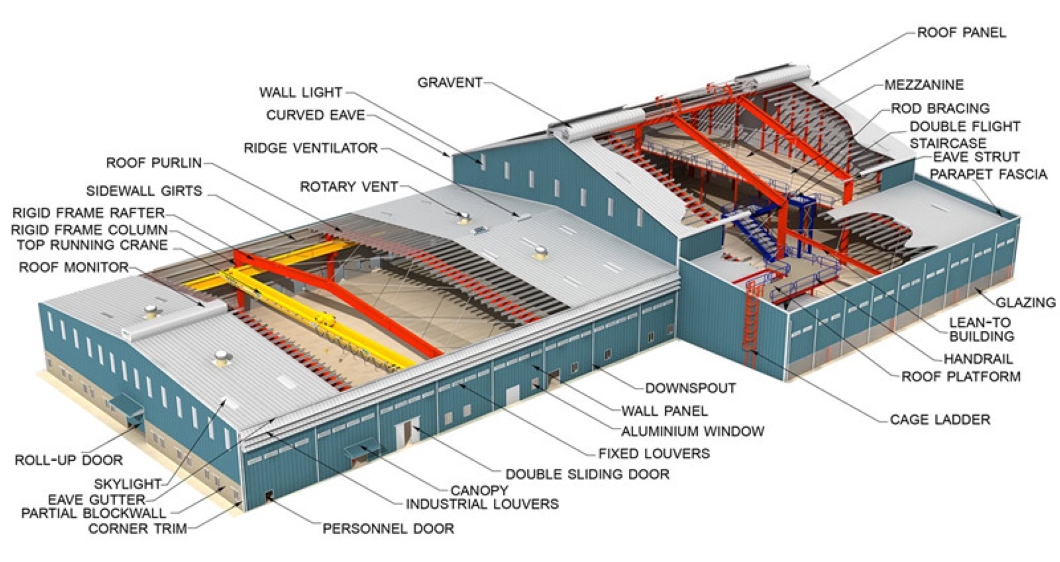

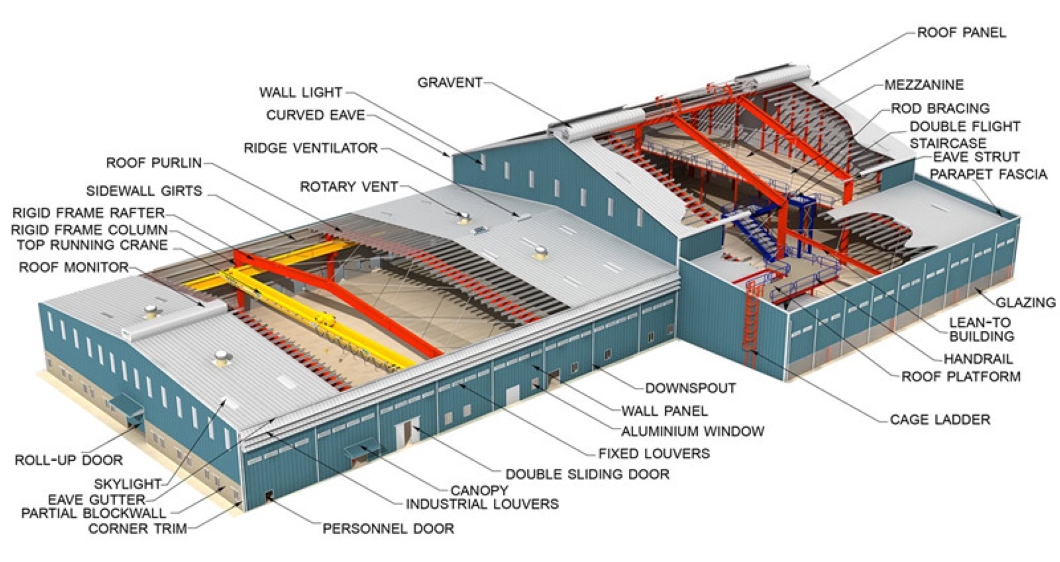

The construction of steel structure office building

1. The layout of the steel structure’s primary and secondary steel beams should combine with the attic construction, decoration, and installation design to avoid or reduce the secondary damage to the steel structure during the decoration and installation process.

2. It is not recommended to use hollow steel such as square steel, tube steel, etc., because it is difficult to paint anti-rust paint inside the steel, the temperature changes in the north, and the rust of the steel condensed water will pollute the ceiling and wall, and seriously endanger safety.

3. The force of the steel structure layout must be clear, and the force transmission route must be clear and concise. Because the steel structure itself has obvious force and vibration, strict analysis and calculation are required to control the structural deformation strictly and vibration frequency to ensure the visual beauty of the structure, eliminate the resonance of the structure and human activities, and avoid shear fatigue damage of the structure due to resonance. At the same time, it can guarantee comfort during use.

4. For the purchase of profiles, we generally have various specifications to choose from. No matter which specification you choose, it is recommended to use “national standard” steel because its steel quality and specifications are better than “non-standard steel.” Non-standard steel has high hardness, brittle steel, poor ductility, and is not easy to cut or drill.

5. Before fixing the channel steel, the side of the channel steel against the wall should paint with anti-rust paint, but the other parts should paint after the welding is completed. Otherwise, it will affect the welding work.

6. When installing the steel structure, pay attention to that the I-beam and channel steel must be of the same specification, and “full welding” must be selected. The main keel should be whole steel, and intermediate welding is strictly prohibited.

7. Don’t change the structure of the building privately. Whether it is expansion or demolition, it is necessary to communicate and plan with the original builder; otherwise, it is easy to cause unsafe construction.

Product Parameters

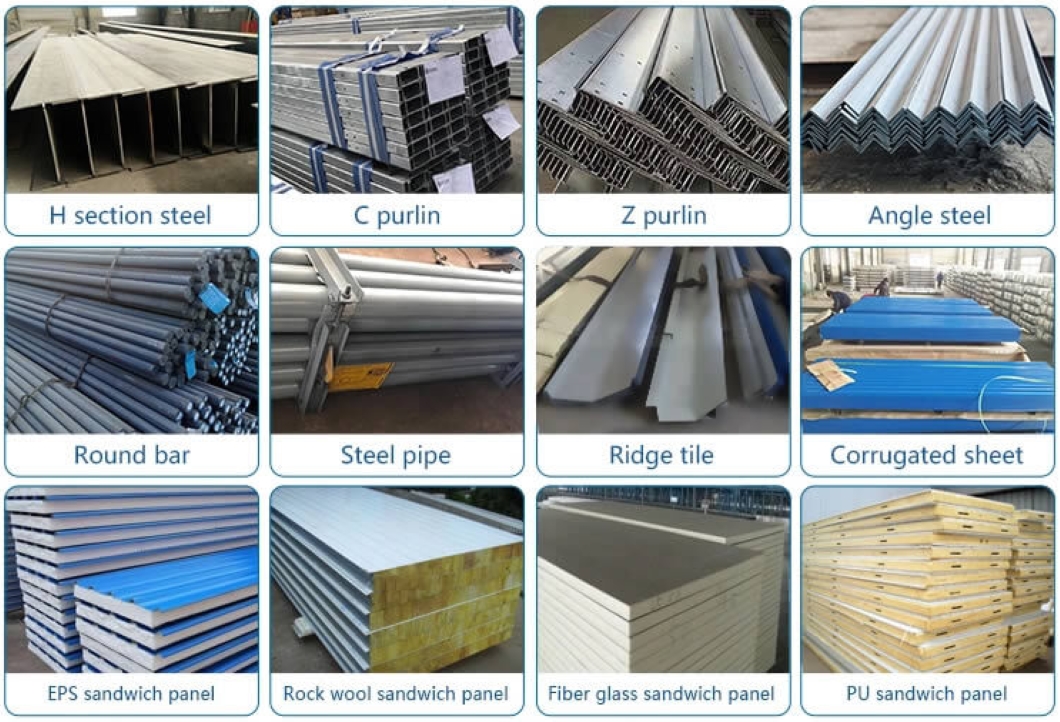

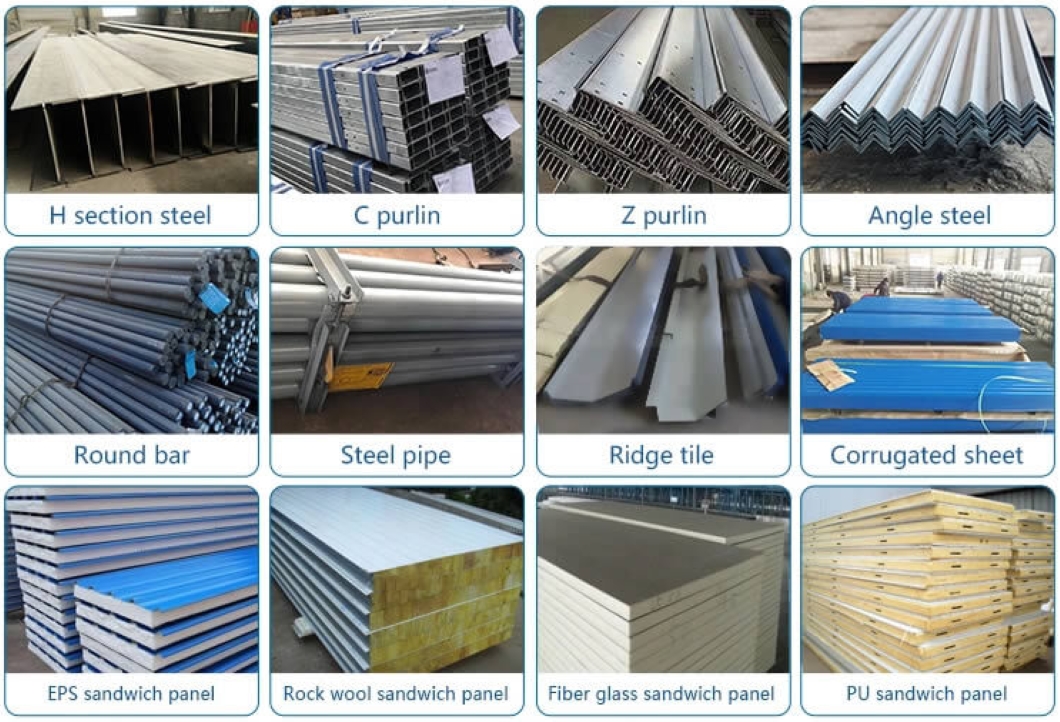

Main Steel Frame

| H section steel | Q235/Q355 grade steel 8mm/10mm |

Welding | Automatic submerged arc welding |

Rust removal | Shot blasting Sa 2.5 |

Surface processing | Alkyd painting or galvanized |

Intensive bolt | Grade 10.9 |

Sub Steel Frame

| Angle brace | L50x4, Steel Q235, processed and painted |

Cross support | Φ20, Steel Q235, processed and painted |

Tie rod | Φ89*3, Steel Q235, processed and painted |

Bracing | Φ12, Steel Q235, processed and painted |

Standard bolt | Galvanized bolt |

Roof

| Purlin | C#160,C#180,C#250, galvanized |

Roof panel | Insulated sandwich panel or corrugated steel plate |

Skylight panel | 2.0mm FRP |

Accessories | Glass cement, self-tapping screws,etc |

Flashing/Trimming | Sheet steel profile |

Gutter | Galvanized sheet steel profile |

Water pipe | Φ110 PVC |

Walls

| Purlin | C#160,C#180,C#250, galvanized |

Wall | Insulated sandwich panel or corrugated steel plate |

Accessories | Glass cement, self-tapping screws,etc |

Flashing/Trimming | Sheet steel profile |

Ventilation | Axial fan |

Doors | Rolling door/sliding door | Automatic or manual |

Windows | Sliding/fixed/shutter | Aluminum or PVC window frame |

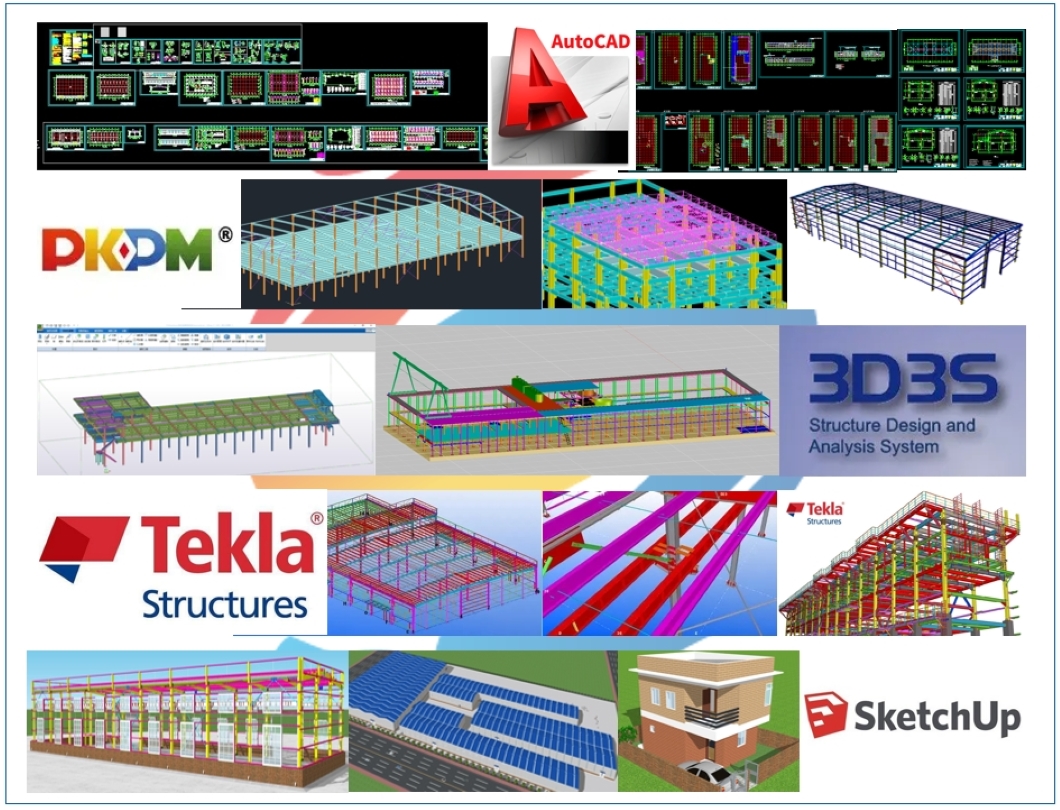

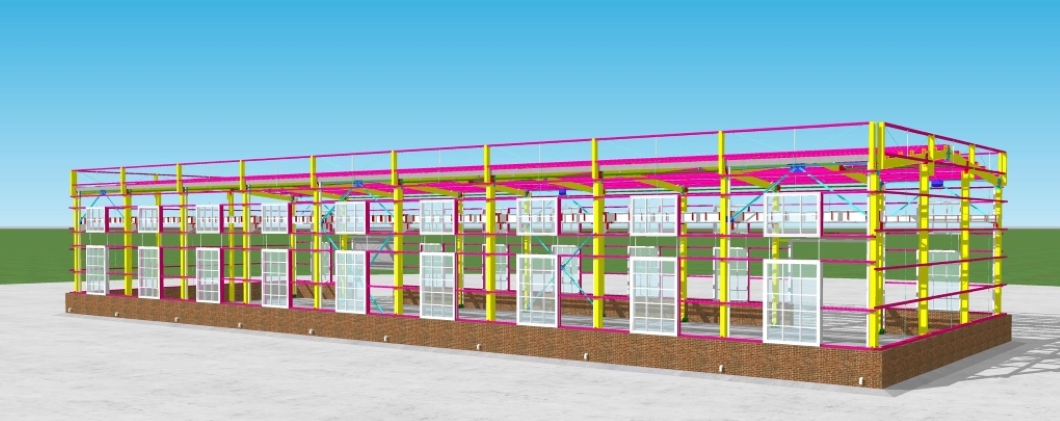

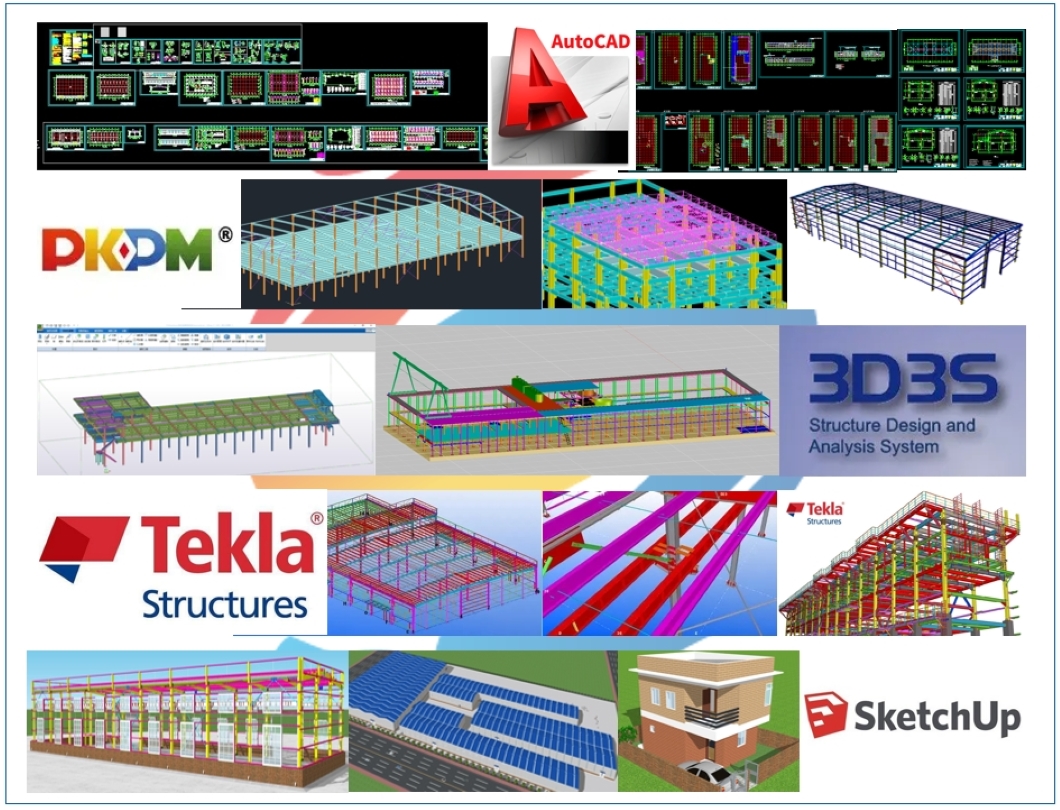

Professional design

1.We have professional design team, working experience more than 10 years;

2.We are a direct factory of steel structure building, we can design drawing according to your request.

Packaging & Shipping

Packaging Details

1. Steel structure components will be in nude packaging with proper protection.

2. Sandwich panels will be packed with plastic film.

3. Doors and windows will be packed with bubble plastic.

4. Bolts and other accessories will be packed in wood boxes.

Normally is 40'HQ and 40'OT container. If you have specifical requirements,40GP and 20GP container are ok

Our technical team will do the economical packing plan for clients, calculate the quantity of steel structure materials accurately and use the min. quantity of containers, to save the shipping freight for clients.

When packing we use the pallets according to container's size, to improve the loading unloading efficency.