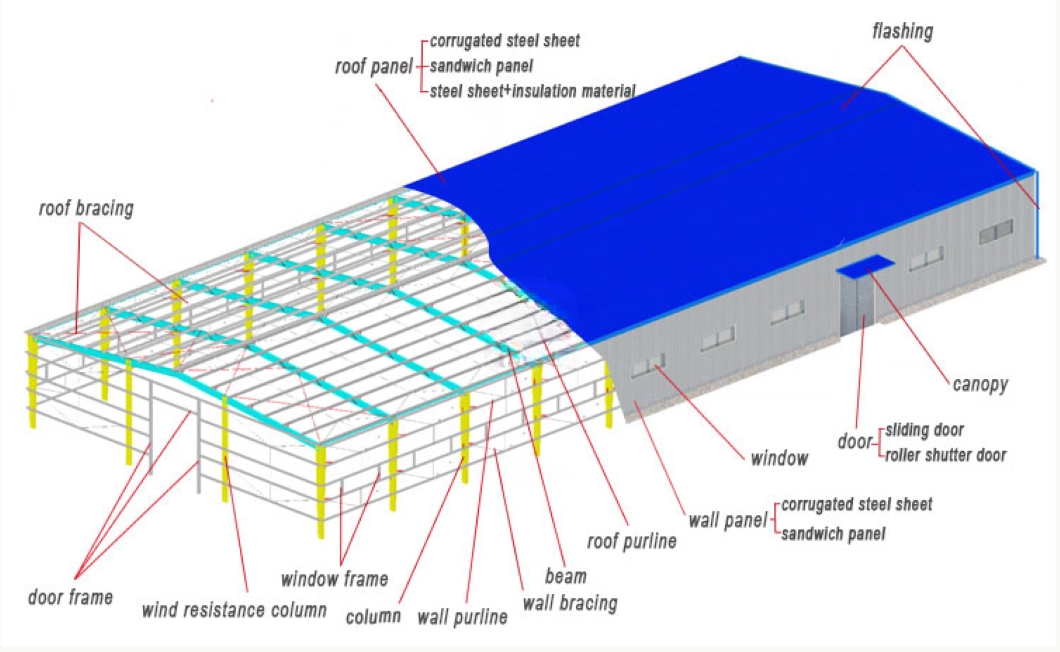

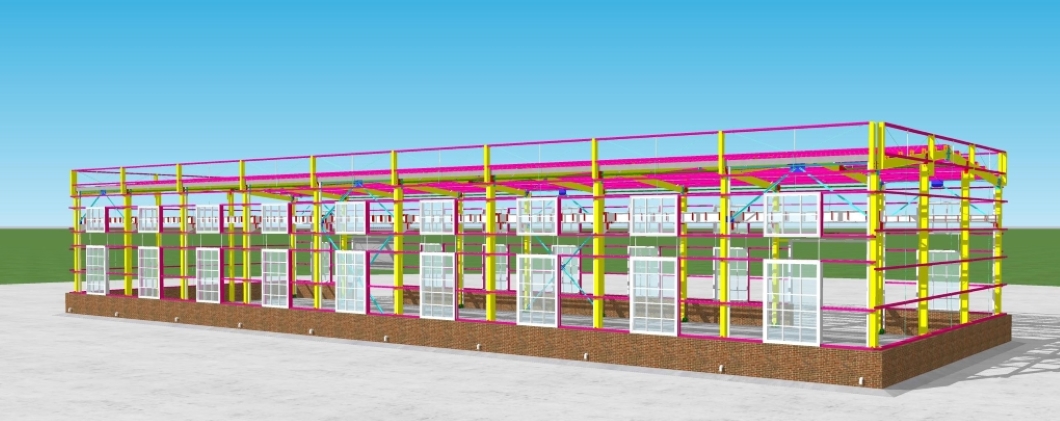

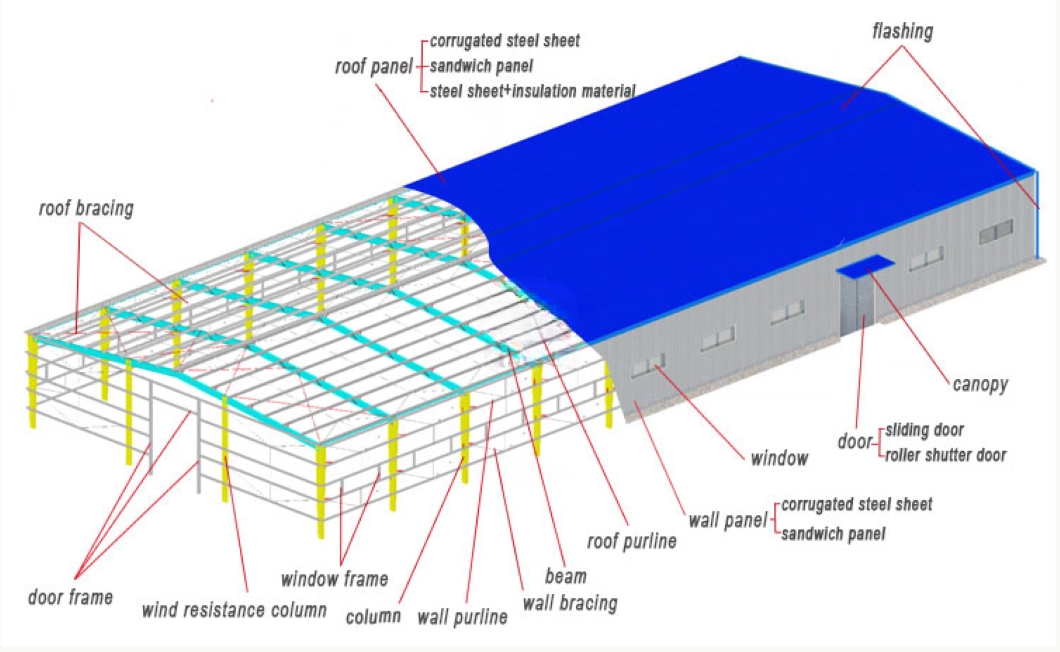

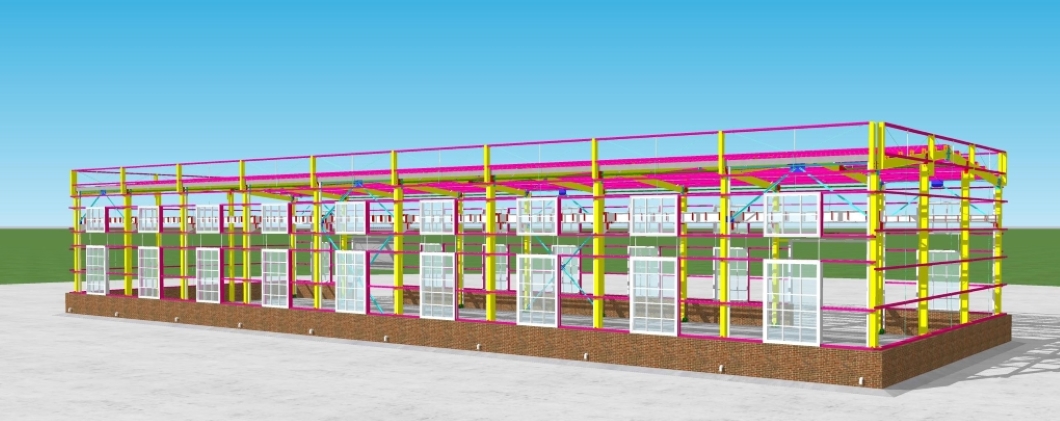

Steel structure building is made from welding H section steel as column and beam, some of them has crane beam, it's made from H steel beam too.Galvanized C ,Z section steel as wall purlin and roof purlin, Its wall and roof are made of metal steel sheet or sandwich panel. The door is electric shutter door or flat open door. Window is pvc or aluminum window. With the extensiveuse of steel structure,its advantages are increasingly significant compared with traditional building.

Steel structure building has the advantages of light weight, high strength, good toughness, recyclability, good wind and earthquake resistance, and is suitable for industrial buildings such as factory buildings, warehouses, and workshops.

Product Features

1. Easy to assemble

The steel components arriving at the construction site are all prefabricated. During the construction process, the installation work needs to layout each structure and erect it according to the installation drawing.

2. Reasonable cost

The steel structure building is light in weight, reducing the basic cost, and the construction speed is fast. It can be completed and put into production as soon as possible. The overall economic benefits are much better than that of the concrete structure

3. Simple construction, short construction period

The production and installation of steel structure usually involve processing all required components in the factory and then transporting to the construction site to assemble. So the construction period is greatly shortened.

4. Energy-saving and environmentally friendly

The corrugated color steel sheet and sandwich panels used in the prefab steel structure workshop are all energy-saving materials. The steel structure also adopts dry construction during the construction process to avoid dust and environmental pollution caused by concrete construction

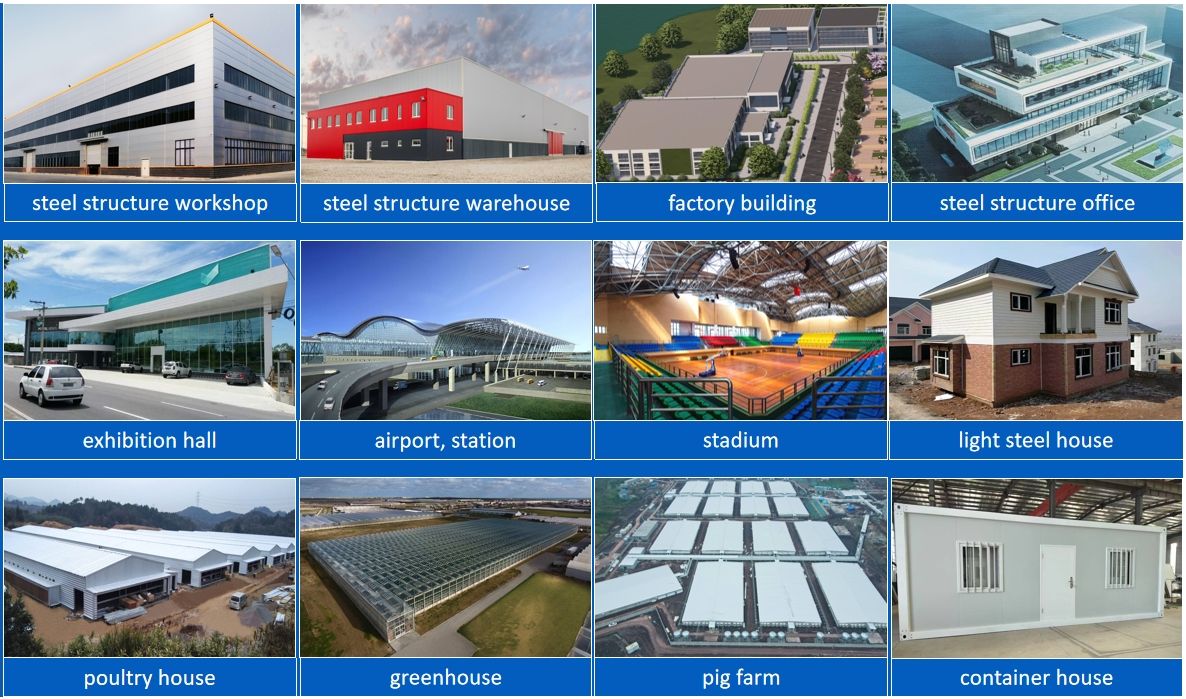

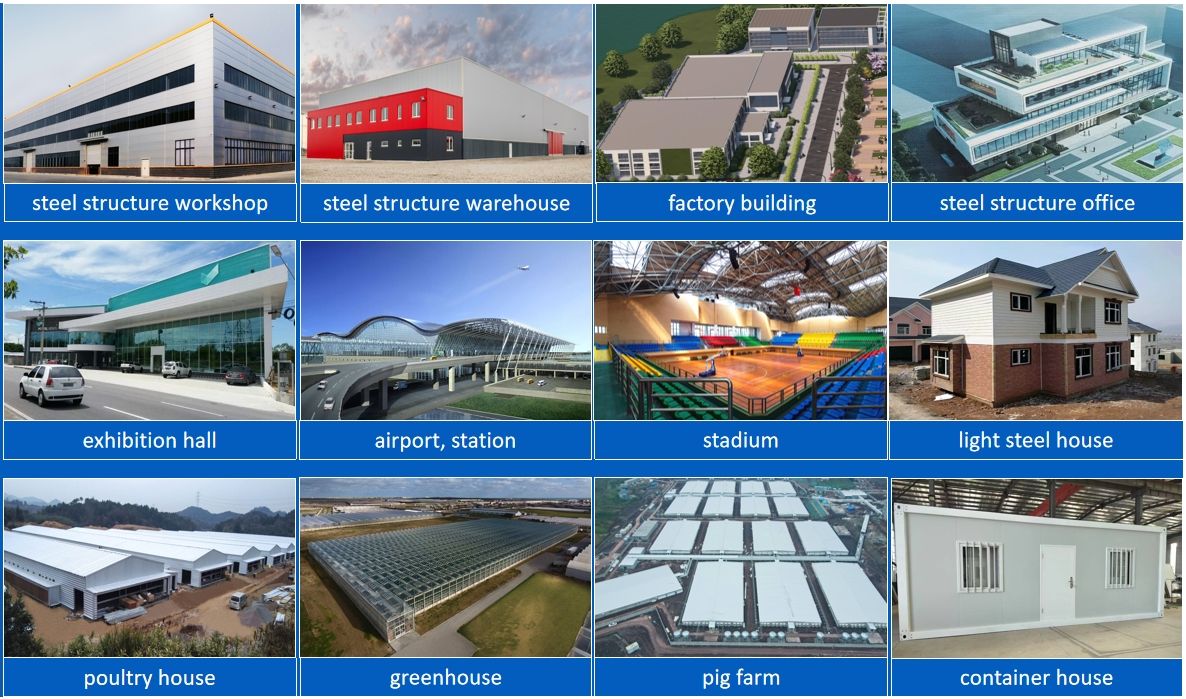

Product Usage

The steel structure buildings has been widely used in various situation, such as steel storage warehouse, workshops, conference halls, large shopping malls, exhibition halls, hangar, plant, stadiums and other large public event buildings. It has many advantages as far as the sustainable development is concerned in the modern industry

Product Parameters

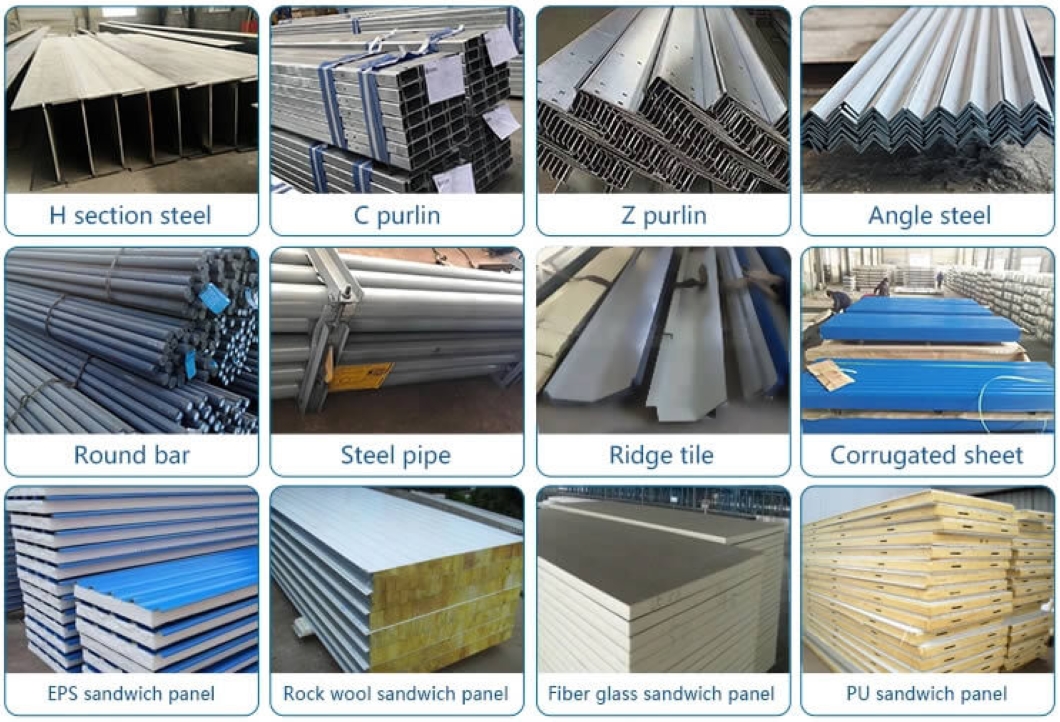

Items | Specifications |

Main Steel Frame

| Column | Q235B, Q355B Welded H Section Steel |

Beam | Q235B, Q355B Welded H Section Steel |

Secondary Frame

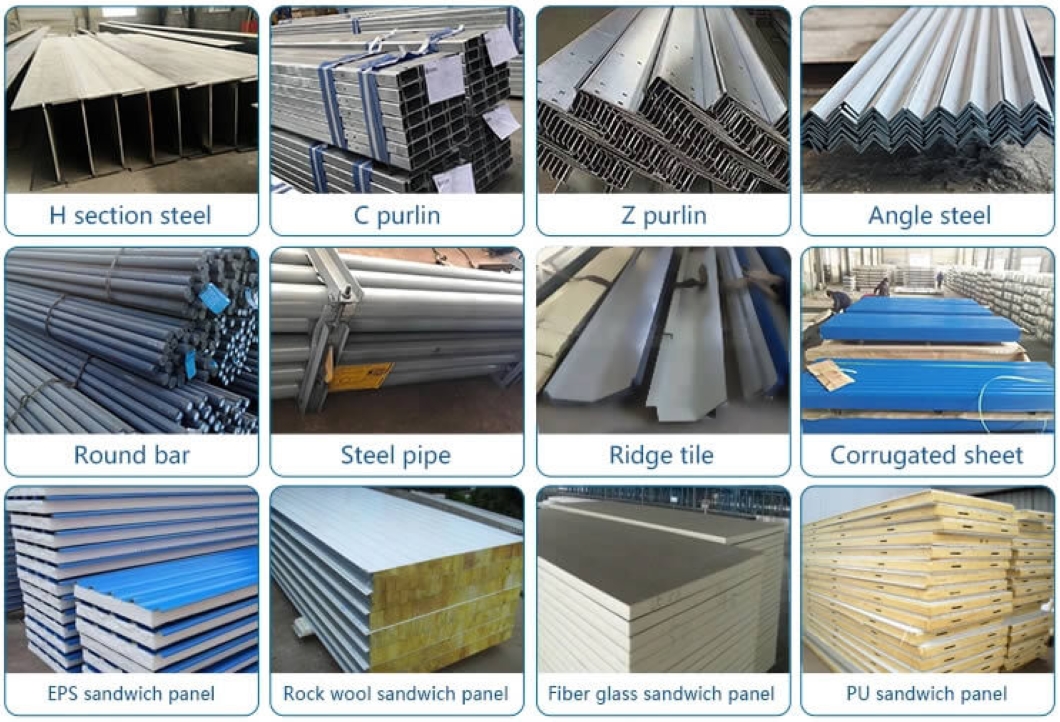

| Purlin | Q235B C and Z Purlin |

Knee Brace | Q235B Angle Steel |

Tie Rod | Q235B Circular Steel Pipe |

Brace | Q235B Round Bar |

Vertical & Horizontal support | Q235 Angle Steel, Round Bar, or Steel Pipe |

Enclosure System

| Roof Panel | EPS, Glass Fiber, Rock Wool, Pu Sandwich Panel Corrugated Steel Sheet |

Wall Panel | EPS, Glass Fiber, Rock Wool, Pu Sandwich Panel Corrugated Steel Sheet |

Accessories

| Window | Aluminum Window, Plastic Steel Window |

Door | Aluminum Door, Rolling Metal Door |

Rainspout | PVC |

Fastener | High Strength Bolts, Normal Bolts, Chemical Bolts |

Ventilation System | Natural Ventilator, Ventilation Shutters |

Live Load on Roof | In 120kg Sqm (Color steel panel surrounded) |

Wind Resistance Grade | 12 Grades |

Earthquake-Resistance | 8 Grades |

Structure Usage | Up to 50 years |

Temperature | Suitable temperature -50°C~+50°C |

Certification | CE, SGS,ISO9001:2008,ISO14001:2004 |

Finishing Options | Vast array of colors and textures available |

Product Installation

We will provide installation drawings, installation videos. If necessary, we will have dedicated staffs and engineers to the scene to guide the installation. loading and unloading of our products are convenient. You can use crane in the destination,two people can discharge whole products within half an hour. And definitely won't destroy packaging.

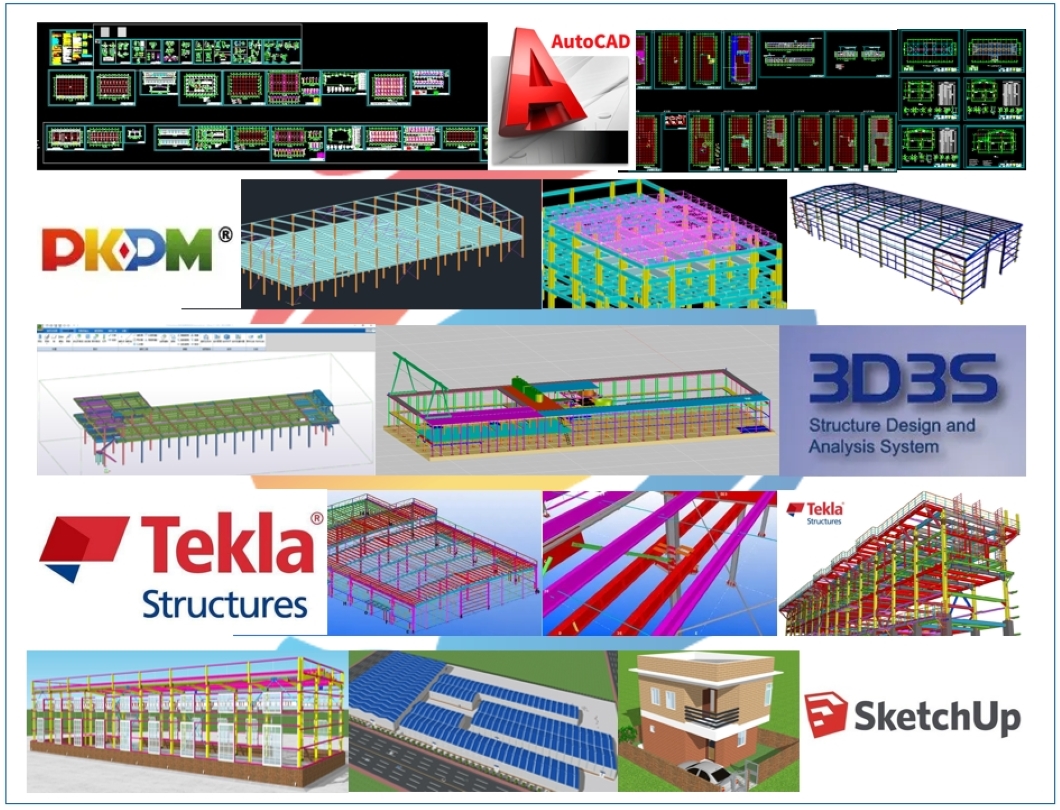

Professional design

1.We have professional design team, working experience more than 10 years;

2.We are a direct factory of steel structure building, we can design drawing according to your request.

Packaging & Shipping

Packaging Details

1. Steel structure components will be in nude packaging with proper protection.

2. Sandwich panels will be packed with plastic film.

3. Doors and windows will be packed with bubble plastic.

4. Bolts and other accessories will be packed in wood boxes.

Normally is 40'HQ and 40'OT container. If you have specifical requirements,40GP and 20GP container are ok

Our technical team will do the economical packing plan for clients, calculate the quantity of steel structure materials accurately and use the min. quantity of containers, to save the shipping freight for clients.

When packing we use the pallets according to container's size, to improve the loading unloading efficency.