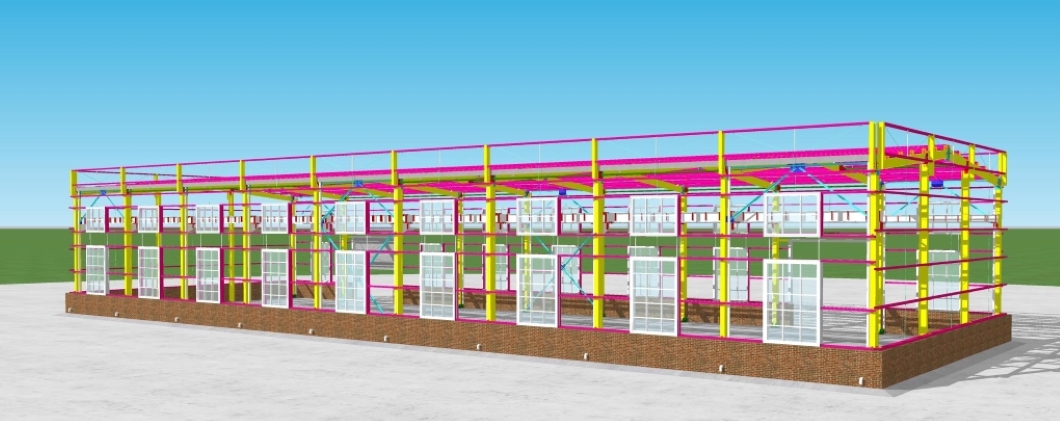

A steel structure warehouse is a type of industrial building that utilizes steel as the primary material for its construction. These warehouses are designed to provide a durable, spacious, and efficient storage solution for a wide range of goods and materials.

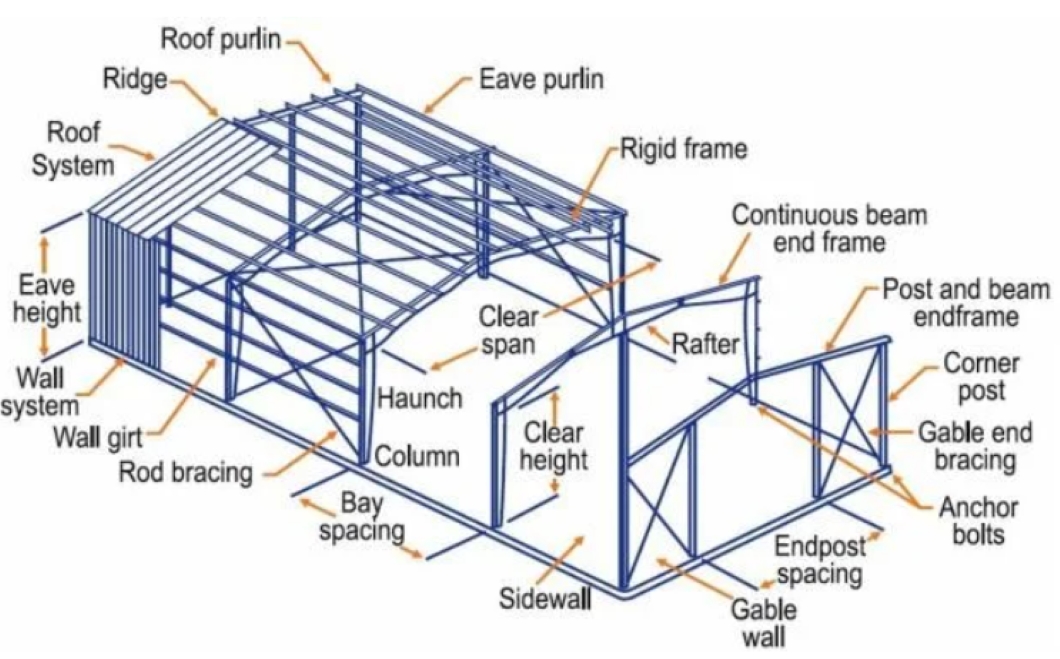

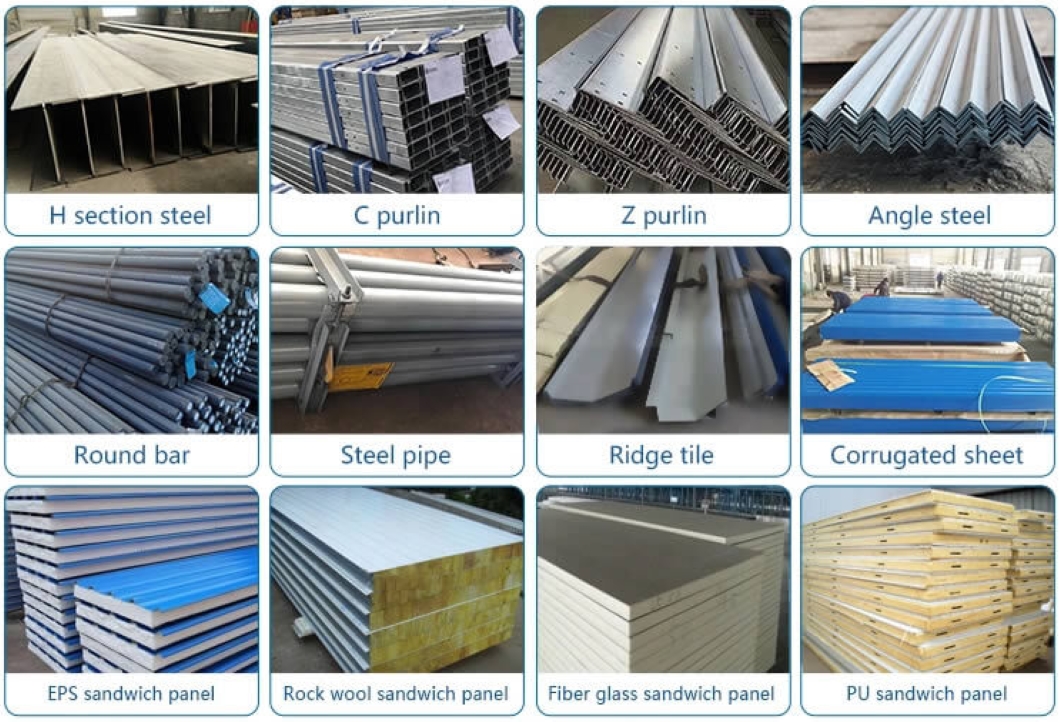

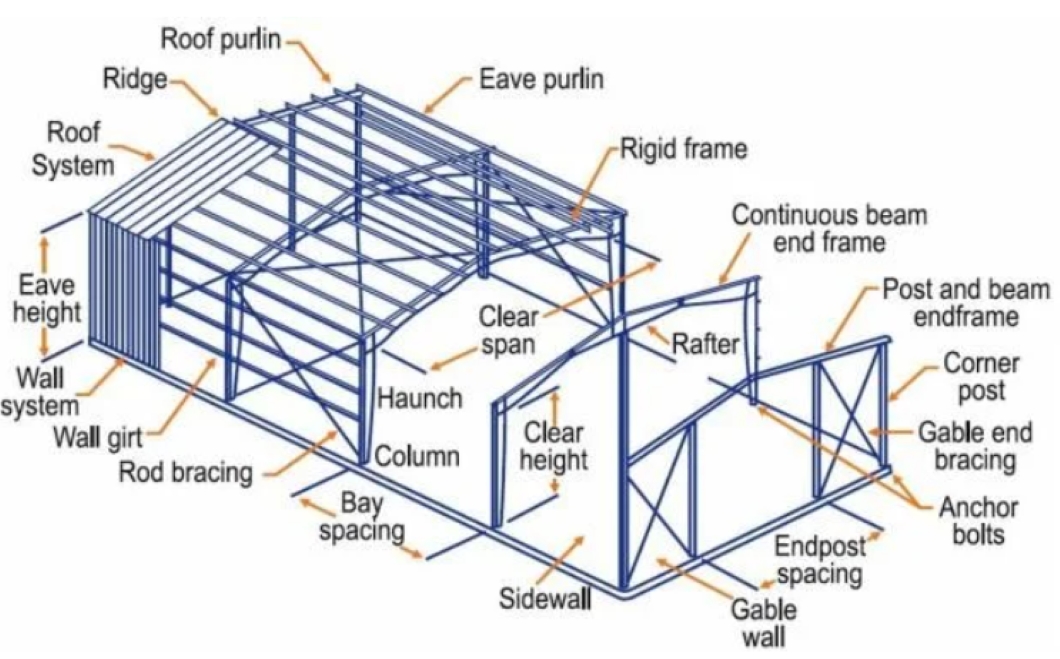

A steel structure warehouse typically consists of a steel framework that supports the roof and walls. The framework is made up of steel beams, columns, and braces, which are interconnected through welding, bolting, or riveting. The roof and walls can be made of various materials, such as steel sheets, corrugated metal, or insulated panels, depending on the specific requirements of the warehouse.

Product Features

Durability and Strength: Steel is a highly durable and strong material, making steel structure warehouses capable of withstanding harsh weather conditions and heavy loads. This ensures that the warehouse remains structurally sound and functional for many years.

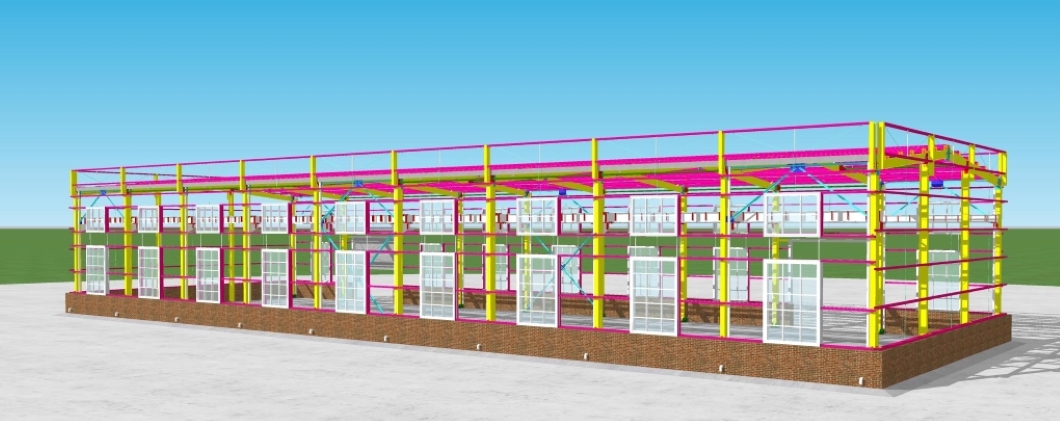

Large Span Capability: Steel structures can span long distances without the need for intermediate supports, allowing for the creation of large, open spaces that are ideal for warehousing. This feature maximizes the storage capacity and flexibility of the warehouse.

Rapid Construction: Steel structures can be prefabricated in factories and assembled on-site, significantly reducing construction time. This allows for faster completion of the warehouse and earlier utilization of the space.

Cost-Effectiveness: While the initial investment in steel may be higher than traditional construction materials, the long-term cost savings associated with steel's durability, low maintenance requirements, and energy efficiency often make it a cost-effective choice.

Flexibility and Customization: Steel structures offer a high degree of flexibility and customization, allowing for the creation of warehouses that are tailored to specific storage needs and requirements. This includes the ability to modify the size, layout, and features of the warehouse as needed.

Environmental Sustainability: Steel is a recyclable material, and steel structure warehouses can be dismantled and the materials reused or recycled at the end of their lifespan. This reduces waste and promotes environmental sustainability.

Product Parameters

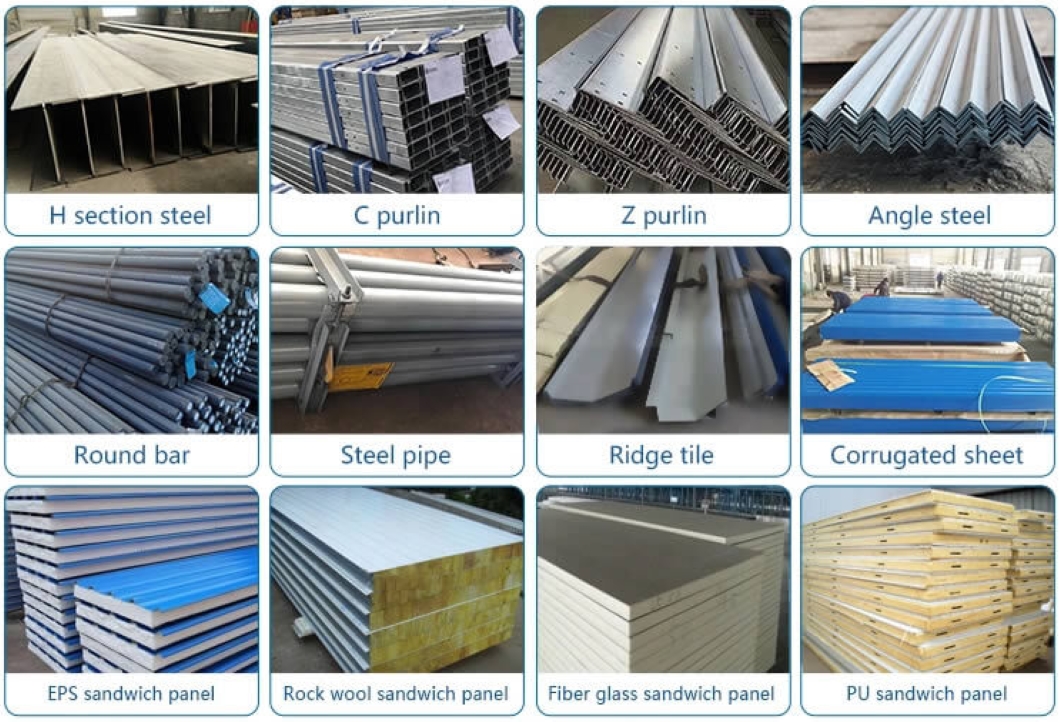

Main Steel Frame

| H section steel | Q235/Q355 grade steel 8mm/10mm |

Welding | Automatic submerged arc welding |

Rust removal | Shot blasting Sa 2.5 |

Surface processing | Alkyd painting or galvanized |

Intensive bolt | Grade 10.9 |

Sub Steel Frame

| Angle brace | L50x4, Steel Q235, processed and painted |

Cross support | Φ20, Steel Q235, processed and painted |

Tie rod | Φ89*3, Steel Q235, processed and painted |

Bracing | Φ12, Steel Q235, processed and painted |

Standard bolt | Galvanized bolt |

Roof

| Purlin | C#160,C#180,C#250, galvanized |

Roof panel | Insulated sandwich panel or corrugated steel plate |

Skylight panel | 2.0mm FRP |

Accessories | Glass cement, self-tapping screws,etc |

Flashing/Trimming | Sheet steel profile |

Gutter | Galvanized sheet steel profile |

Water pipe | Φ110 PVC |

Walls

| Purlin | C#160,C#180,C#250, galvanized |

Wall | Insulated sandwich panel or corrugated steel plate |

Accessories | Glass cement, self-tapping screws,etc |

Flashing/Trimming | Sheet steel profile |

Ventilation | Axial fan |

Doors | Rolling door/sliding door | Automatic or manual |

Windows | Sliding/fixed/shutter | Aluminum or PVC window frame |

Packaging & Shipping

Packaging Details

1. Steel structure components will be in nude packaging with proper protection.

2. Sandwich panels will be packed with plastic film.

3. Doors and windows will be packed with bubble plastic.

4. Bolts and other accessories will be packed in wood boxes.

Normally is 40'HQ and 40'OT container. If you have specifical requirements,40GP and 20GP container are ok

Our technical team will do the economical packing plan for clients, calculate the quantity of steel structure materials accurately and use the min. quantity of containers, to save the shipping freight for clients.

When packing we use the pallets according to container's size, to improve the loading unloading efficency.