This project consists of two buildings, with the first warehouse building covering an area of approximately 3,400 square meters and the second factory building covering an area of approximately 11,000 square meters, constructed using a common portal steel structure framework. The walls and roofs are all made of color steel sheets .

Main Components

The main components of steel workshop include steel column, steel beam, wind-proof column and crane beam.

Steel column: It can be a H-shaped steel column with a constant cross-section or a H-shaped steel column with a variable cross-section.

It is easy to manufacture, safe and reliable, and the main material is Q235B or Q345B.

When the horizontal span of the steel workshop building does not exceed 15m and the column height does not exceed 6m, the steel column should be made of H-shaped steel with equal cross section.

When the span of the factory building is greater than 15m and the column height exceeds 6m, the variable-section steel column should be adopted.

Steel beam: Commonly used welded composite steel beams consist of an I-shaped section consisting of upper and lower flange plates and webs. The main material is Q235B or Q345B.

Wind- resistant column: The wind-resistant column is the structural component of the gable wall. The function of the wind-resistant column is mainly to transmit the wind load of the gable wall. The upper part is transmitted to the entire steel frame structure through the connection with the steel beam, and the lower part is transmitted to the foundation through the connection with the foundation. The main material It is Q235B or Q345B.

Crane beam: The beam used to install the crane track is called the crane beam, which is generally installed on the upper part of the factory building.

Secondary Components

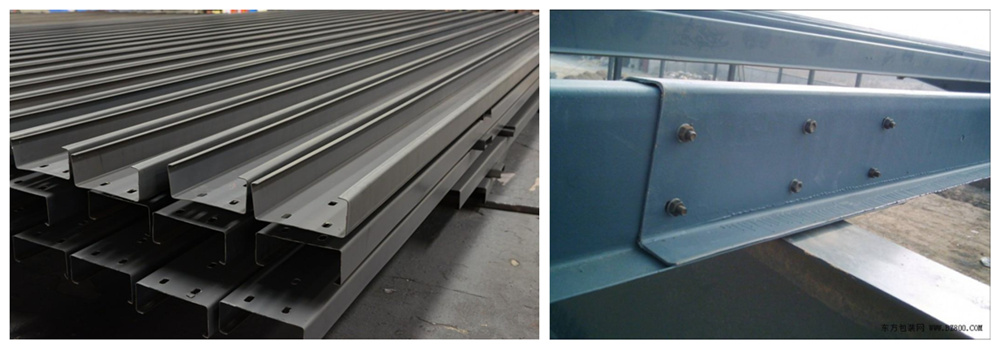

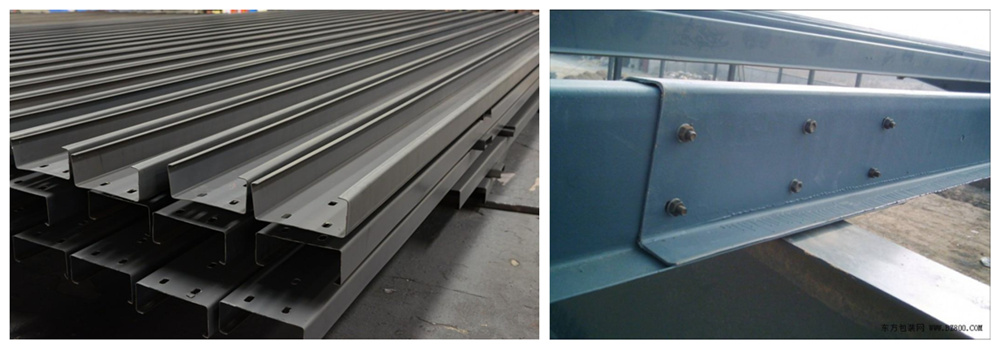

Purlin

Purlin is made of C-shaped steel and Z-shaped steel. The purlin is used to support the roof and wall panels and transfer the load from the roof and wall panels to the main steel frame.

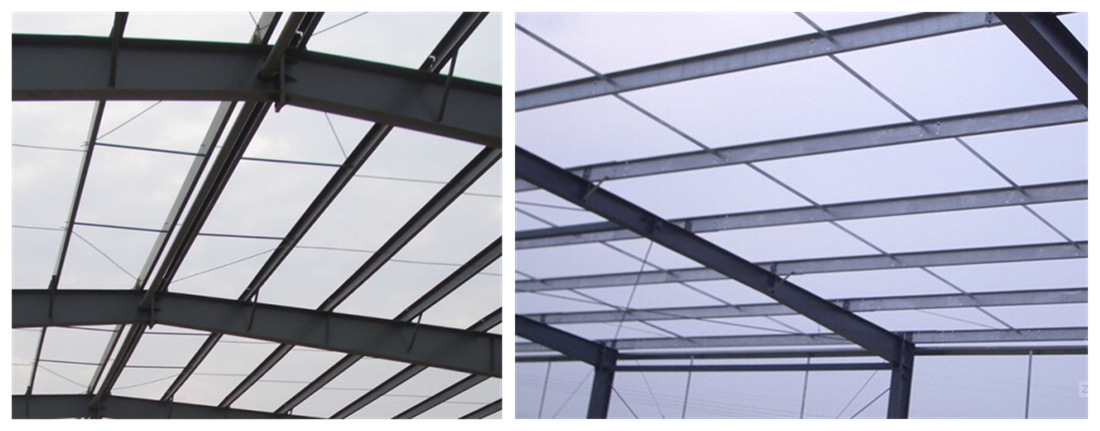

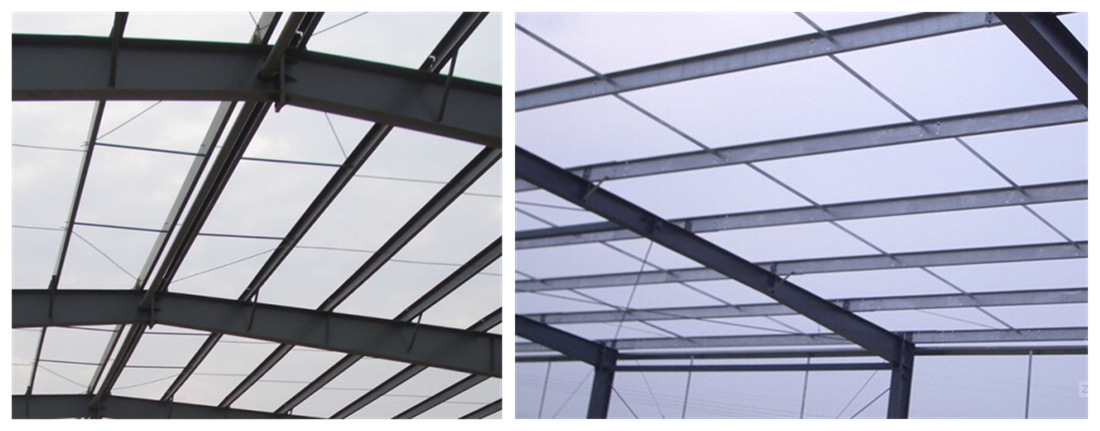

Bracing system

There are roof bracing and wall bracing. The bracing is usually made of steel rods, L angles or square tubes. The bracing system is used to stabilize the steel frame.

Sag rod

The sag rod connects two purlins to adjust and control the stability of two adjacent purlins. Generally, a sag rod is made of a rod with a diameter of 12 or 14 mm.