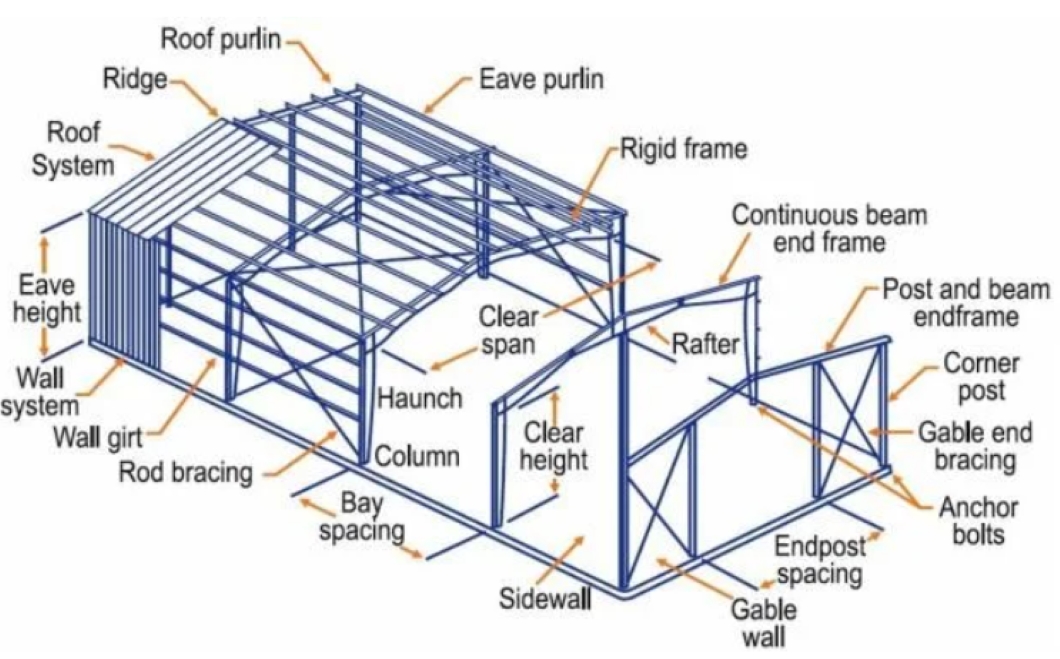

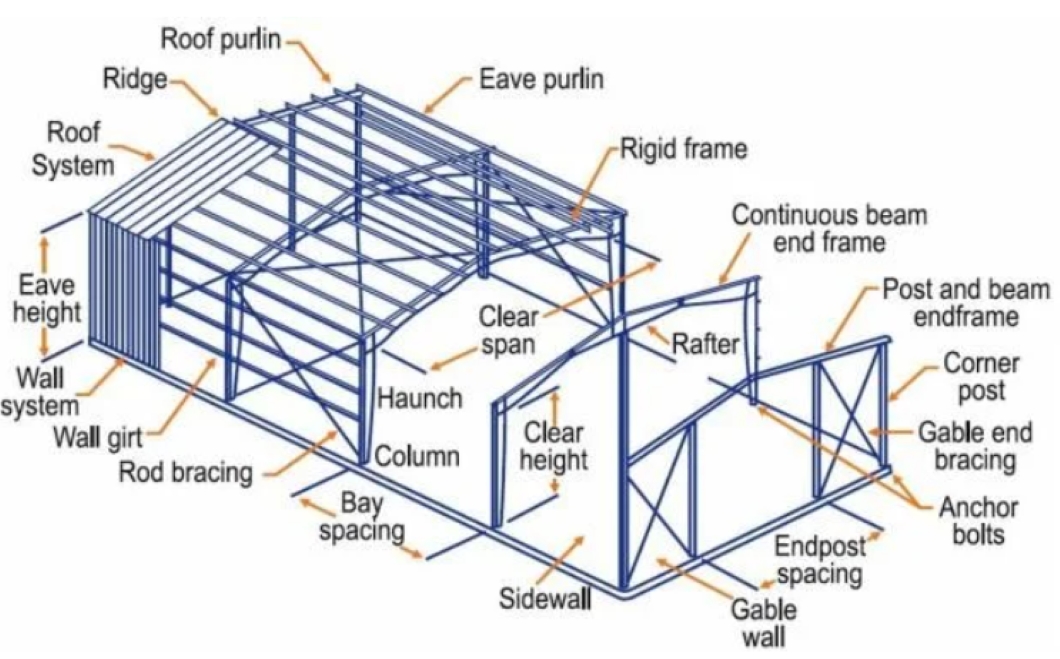

A steel structure warehouse typically consists of a steel framework that supports the roof and walls. The framework is made up of steel beams, columns, and braces, which are interconnected through welding, bolting, or riveting. The roof and walls can be made of various materials, such as steel sheets, corrugated metal, or insulated panels, depending on the specific requirements of the warehouse.

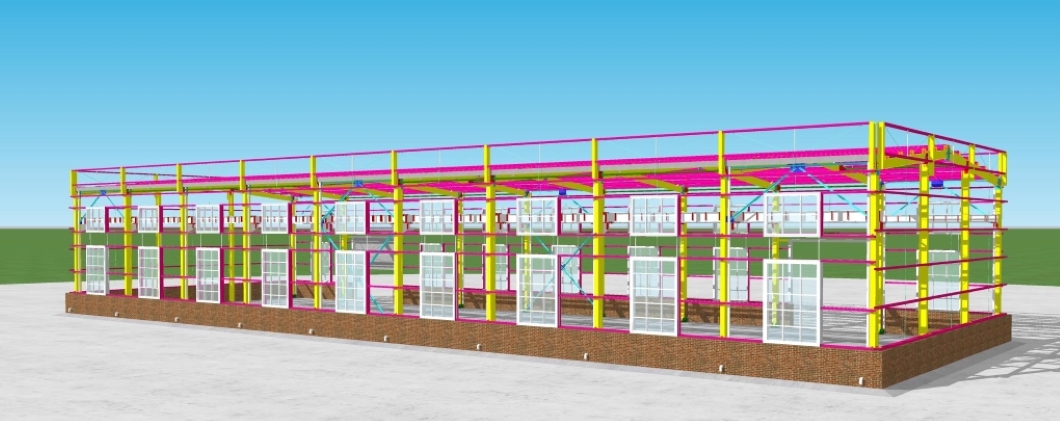

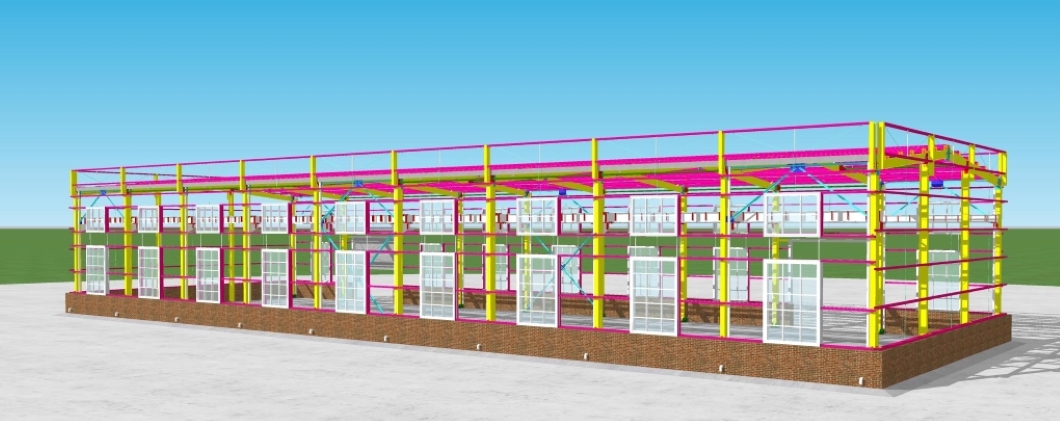

The interior of the warehouse is designed to maximize storage capacity and accessibility. This may include the installation of racking systems, mezzanine floors, and other storage solutions. The warehouse may also be equipped with doors, windows, and other openings to facilitate the loading and unloading of goods.

Product Features

Durability and Strength: Steel is a highly durable and strong material, making steel structure warehouses capable of withstanding harsh weather conditions and heavy loads. This ensures that the warehouse remains structurally sound and functional for many years.

Large Span Capability: Steel structures can span long distances without the need for intermediate supports, allowing for the creation of large, open spaces that are ideal for warehousing. This feature maximizes the storage capacity and flexibility of the warehouse.

Rapid Construction: Steel structures can be prefabricated in factories and assembled on-site, significantly reducing construction time. This allows for faster completion of the warehouse and earlier utilization of the space.

Cost-Effectiveness: While the initial investment in steel may be higher than traditional construction materials, the long-term cost savings associated with steel's durability, low maintenance requirements, and energy efficiency often make it a cost-effective choice.

Flexibility and Customization: Steel structures offer a high degree of flexibility and customization, allowing for the creation of warehouses that are tailored to specific storage needs and requirements. This includes the ability to modify the size, layout, and features of the warehouse as needed.

Environmental Sustainability: Steel is a recyclable material, and steel structure warehouses can be dismantled and the materials reused or recycled at the end of their lifespan. This reduces waste and promotes environmental sustainability.

Fire Resistance: Steel has excellent fire resistance properties, which can help protect the warehouse and its contents in the event of a fire. However, it is important to note that the insulation and cladding materials used in the warehouse may not have the same level of fire resistance.

Energy Efficiency: Steel structures can be designed to incorporate energy-efficient features, such as insulation and natural lighting, to reduce energy consumption and operating costs.

Product Parameters

Main Steel Frame

| H section steel | Q235/Q355 grade steel 8mm/10mm |

Welding | Automatic submerged arc welding |

Rust removal | Shot blasting Sa 2.5 |

Surface processing | Alkyd painting or galvanized |

Intensive bolt | Grade 10.9 |

Sub Steel Frame

| Angle brace | L50x4, Steel Q235, processed and painted |

Cross support | Φ20, Steel Q235, processed and painted |

Tie rod | Φ89*3, Steel Q235, processed and painted |

Bracing | Φ12, Steel Q235, processed and painted |

Standard bolt | Galvanized bolt |

Roof

| Purlin | C#160,C#180,C#250, galvanized |

Roof panel | Insulated sandwich panel or corrugated steel plate |

Skylight panel | 2.0mm FRP |

Accessories | Glass cement, self-tapping screws,etc |

Flashing/Trimming | Sheet steel profile |

Gutter | Galvanized sheet steel profile |

Water pipe | Φ110 PVC |

Walls

| Purlin | C#160,C#180,C#250, galvanized |

Wall | Insulated sandwich panel or corrugated steel plate |

Accessories | Glass cement, self-tapping screws,etc |

Flashing/Trimming | Sheet steel profile |

Ventilation | Axial fan |

Doors | Rolling door/sliding door | Automatic or manual |

Windows | Sliding/fixed/shutter | Aluminum or PVC window frame |

Drawings & Quotation

We have professional designers who can provide you with free design solutions according to your requirements. So, if you have any needs, you can contact us at any time.

Please kindly inform us of the information below if you are interested in our products.

1. Project Progress: Is Land Purchased? Is it licensed by the government?

2. Usage: for warehouse, workshop, showroom, etc.

3. Location: In which country will it be built?

4. Local Climate: Wind speed, Snow load (max. Wind speed)

5. Design: Please provide the design drawing. Or do you need us to design for you?

6. Dimension: Length*width*height

7. Crane Beam: Do you need crane beam inside the steel structure?

8. Roof and Wall: determine the panel material, such as color steel panel, and metal sandwich panel.

9. Windows and Doors: what material, quantity, and type?