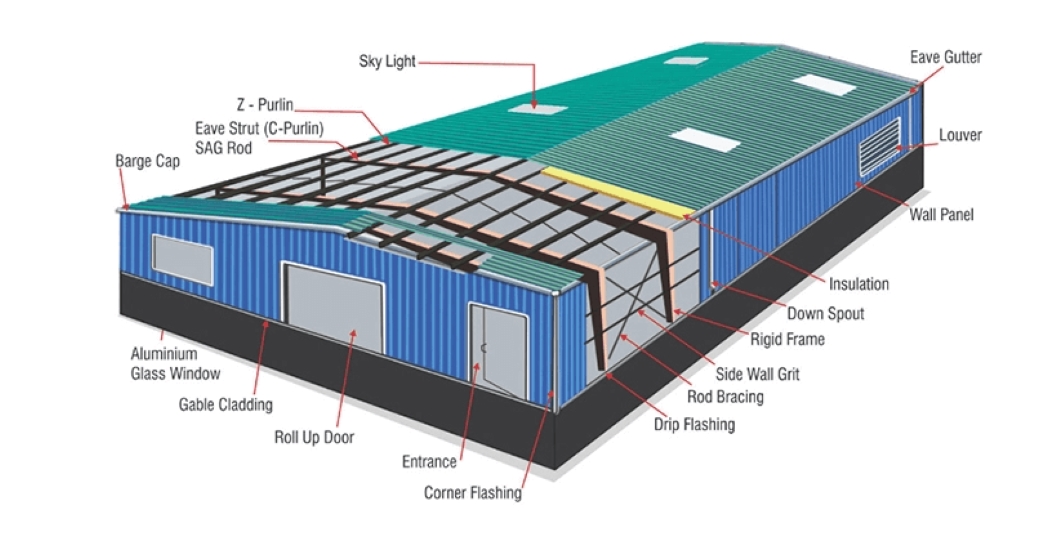

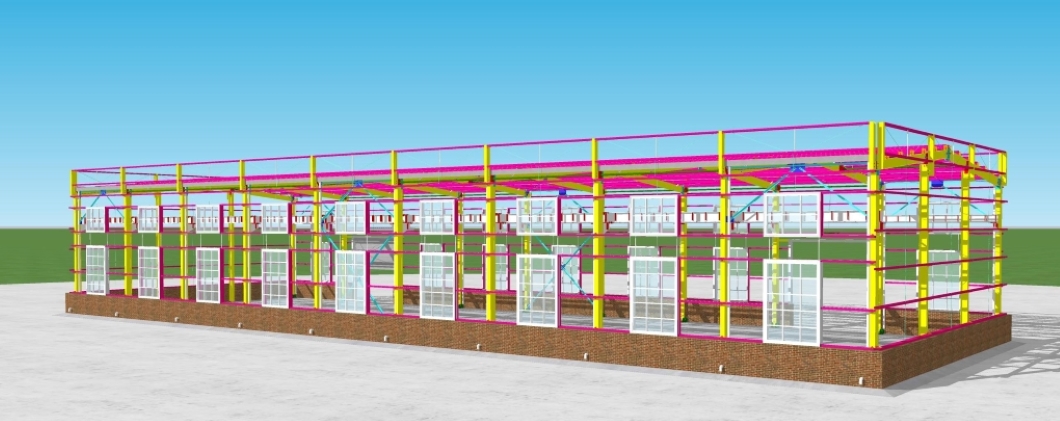

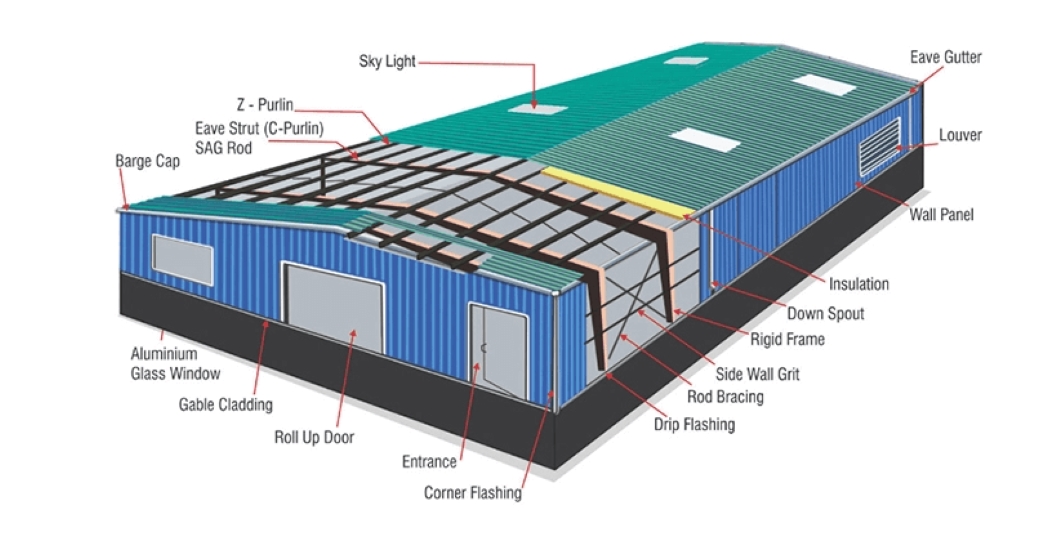

Steel structure building is formed by the main framework through linking up the H beam, C purline, Z purline steel components. Roof and wall using a variety of panels together with other components such as windows and doors. The steel building has the advantages of wide span, high strength, light weight, low cost, temperature protection, save energy, beautiful appearance, short construction time, good effect of insulation, long using life, space-efficient, good seismic performance, flexible layout, etc.

Product Features

1. Wide range of uses: steel buildings can be used not only as production workshops, but also to construct a range of industrial and non-industrial buildings.

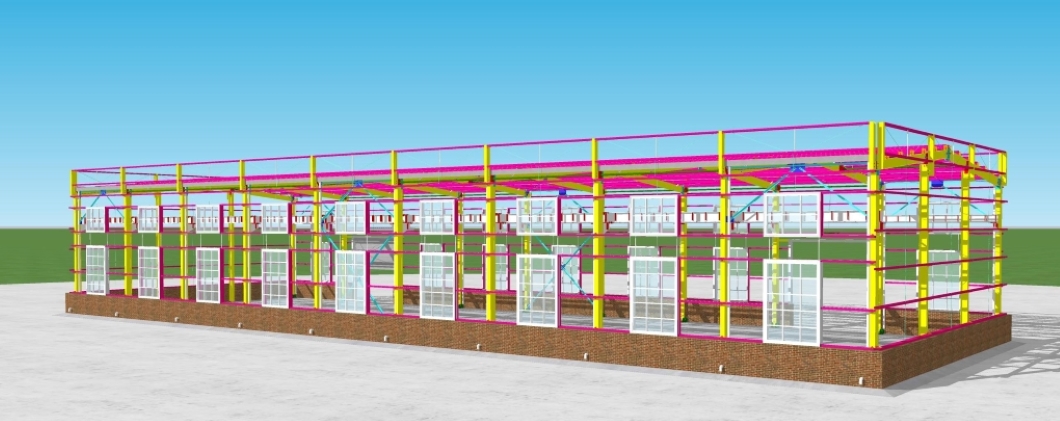

2. Aesthetically pleasing: assembled warehouse buildings are customised at the outset of design to meet requirements. It has a modern linear appearance, with optional external wall colours and roof styles, making it more flexible.

3. Construction is convenient and time-saving: the factory building is 8000 square metres and can be completed in 45 days from start to finish, which greatly saves construction time and is put into use faster.

4. Strong ability to resist natural disasters: With frame structure, the natural forces on the workshop can be well offset to various parts of the workshop under strong wind and strong earthquake environment, thus reducing the impact of natural forces on the workshop.

5. Strong customisation: Any requirement can be met, a truly customised building.

6. Easy to expand: along with the increase in the scale of business, the expansion of the workshop is also easy.

Product Parameters

Items | Specifications |

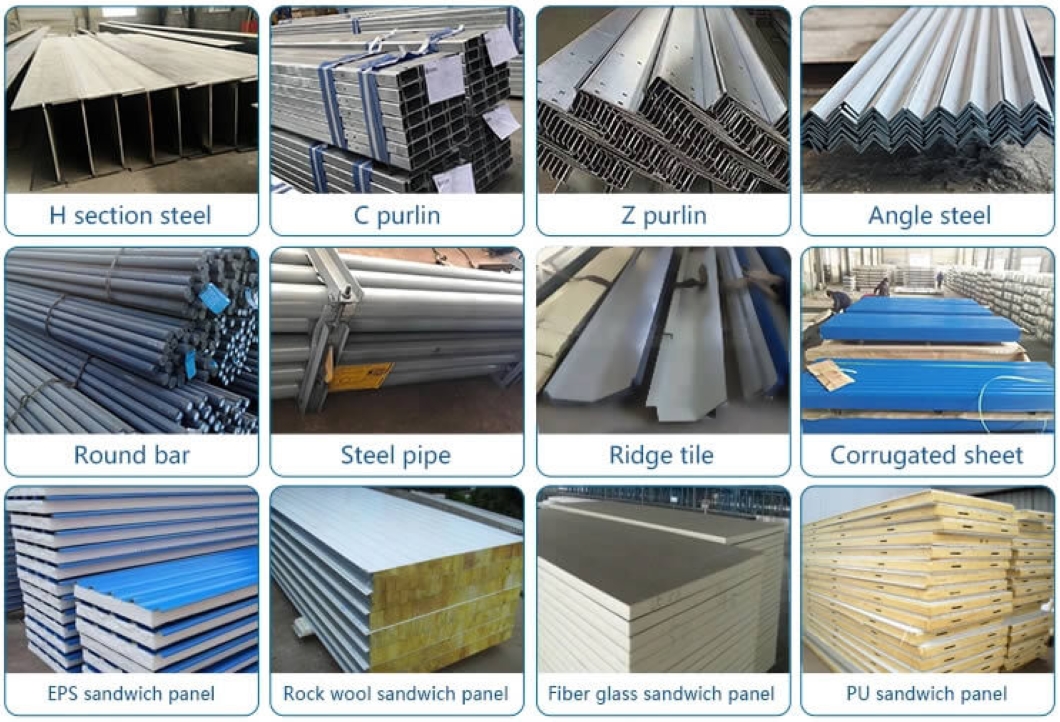

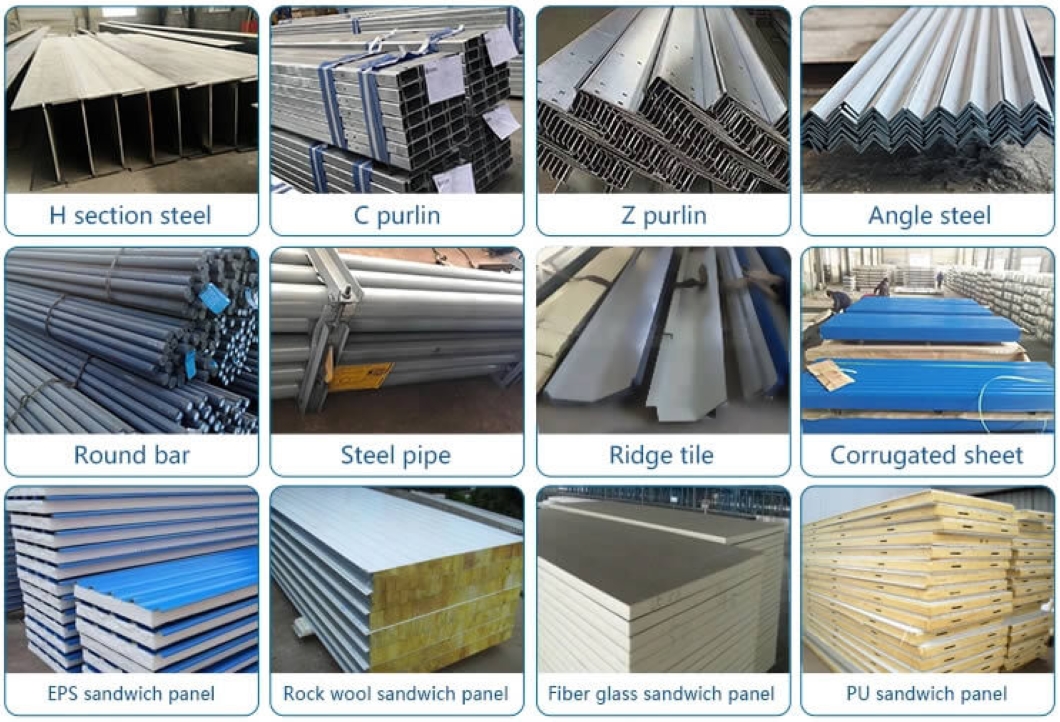

Main Steel Frame

| Column | Q235B, Q355B Welded H Section Steel |

Beam | Q235B, Q355B Welded H Section Steel |

Secondary Frame

| Purlin | Q235B C and Z Purlin |

Knee Brace | Q235B Angle Steel |

Tie Rod | Q235B Circular Steel Pipe |

Brace | Q235B Round Bar |

Vertical & Horizontal support | Q235 Angle Steel, Round Bar, or Steel Pipe |

Enclosure System

| Roof Panel | EPS, Glass Fiber, Rock Wool, Pu Sandwich Panel Corrugated Steel Sheet |

Wall Panel | EPS, Glass Fiber, Rock Wool, Pu Sandwich Panel Corrugated Steel Sheet |

Accessories

| Window | Aluminum Window, Plastic Steel Window |

Door | Aluminum Door, Rolling Metal Door |

Rainspout | PVC |

Fastener | High Strength Bolts, Normal Bolts, Chemical Bolts |

Ventilation System | Natural Ventilator, Ventilation Shutters |

Live Load on Roof | In 120kg Sqm (Color steel panel surrounded) |

Wind Resistance Grade | 12 Grades |

Earthquake-Resistance | 8 Grades |

Structure Usage | Up to 50 years |

Temperature | Suitable temperature -50°C~+50°C |

Certification | CE, SGS,ISO9001:2008,ISO14001:2004 |

Finishing Options | Vast array of colors and textures available |

Production process

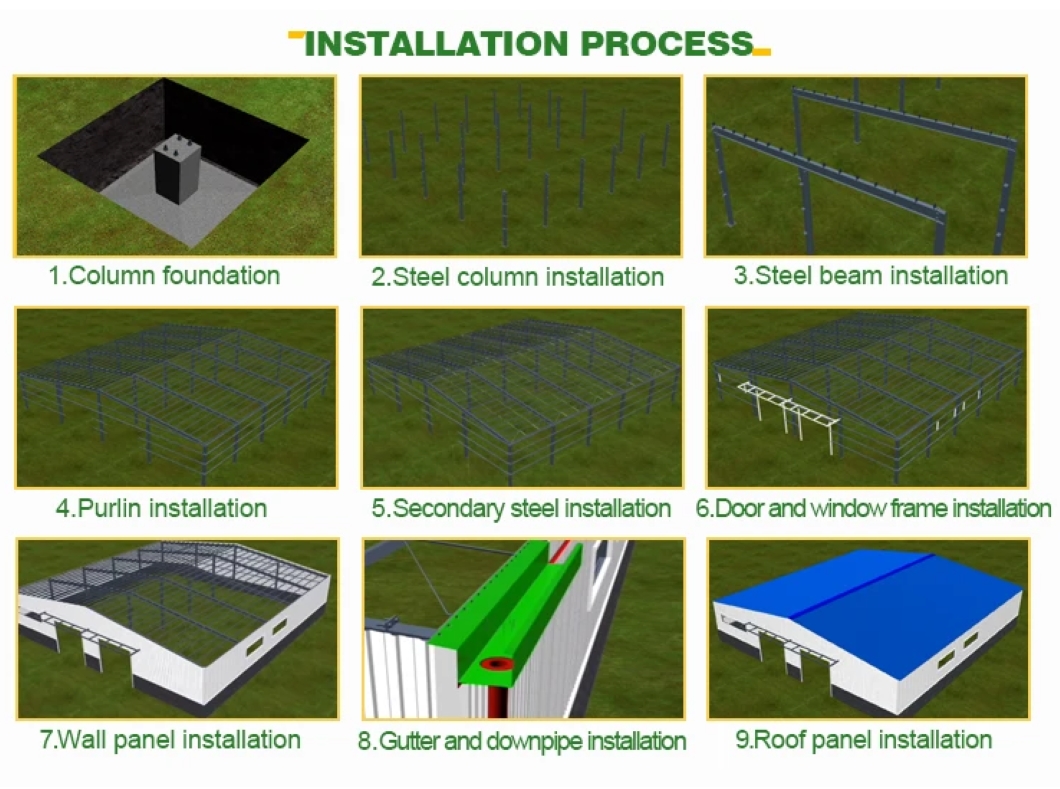

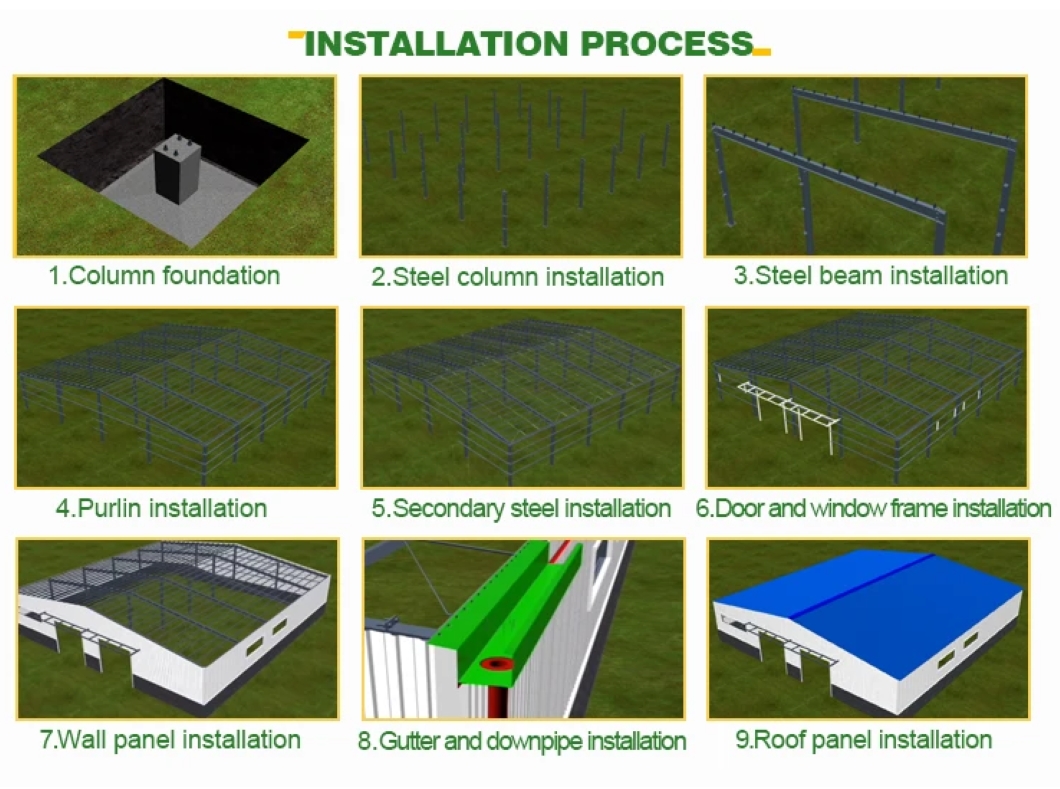

Product Installation

With our top-notch installation support, you can rest assured that setting up your workshop will be a breeze. We provide detailed installation drawings and videos to guide you every step of the way. And if you need extra assistance, our dedicated staff and engineers are ready to be on-site to personally guide you through the process.

But that's not all! Our products are designed with convenience in mind. Loading and unloading them is a piece of cake. You can easily use a crane at the destination, and with just two people, you can unload the entire workshop in under half an hour. And don't worry about damaging the packaging - we guarantee it will remain intact!

When it comes to quality, we don't compromise. Our Customized Modern Space Frame Building Prefab Steel Structure Workshop is built to last. With a 50-year warranty and lifelong responsibility for after-sales service, you can trust that you're investing in a product that will stand the test of time

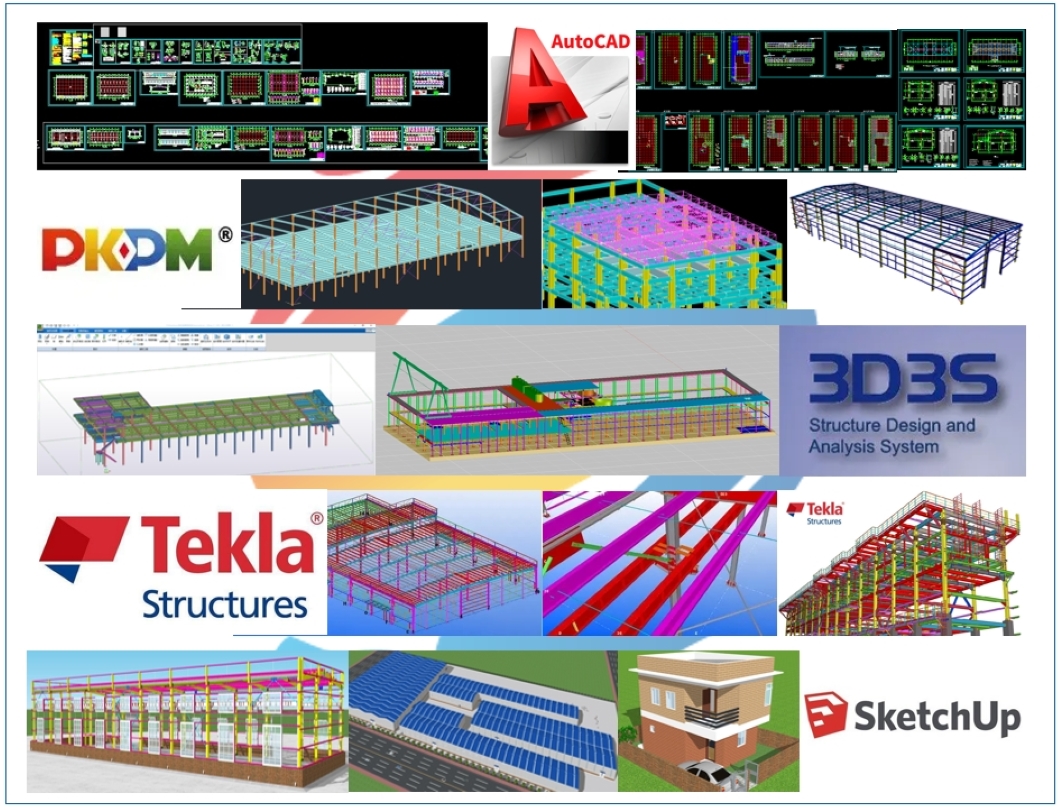

Professional design

1.We have professional design team, working experience more than 10 years;

2.We are a direct factory of steel structure building, we can design drawing according to your request.

Packaging & Shipping

Packaging Details

1. Steel structure components will be in nude packaging with proper protection.

2. Sandwich panels will be packed with plastic film.

3. Doors and windows will be packed with bubble plastic.

4. Bolts and other accessories will be packed in wood boxes.

Normally is 40'HQ and 40'OT container. If you have specifical requirements,40GP and 20GP container are ok

Our technical team will do the economical packing plan for clients, calculate the quantity of steel structure materials accurately and use the min. quantity of containers, to save the shipping freight for clients.

When packing we use the pallets according to container's size, to improve the loading unloading efficency.