Product Description

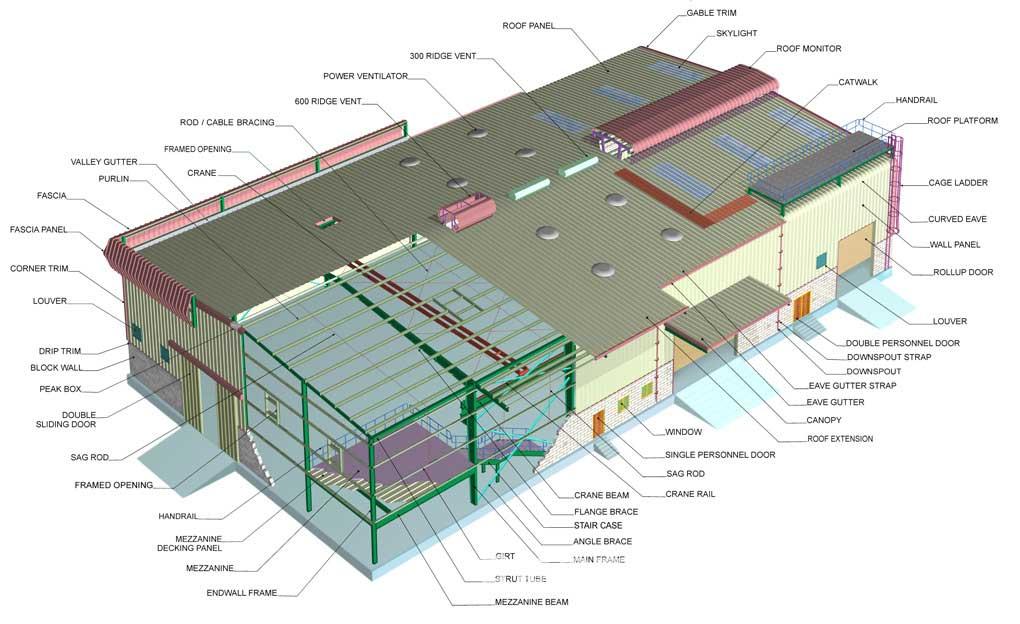

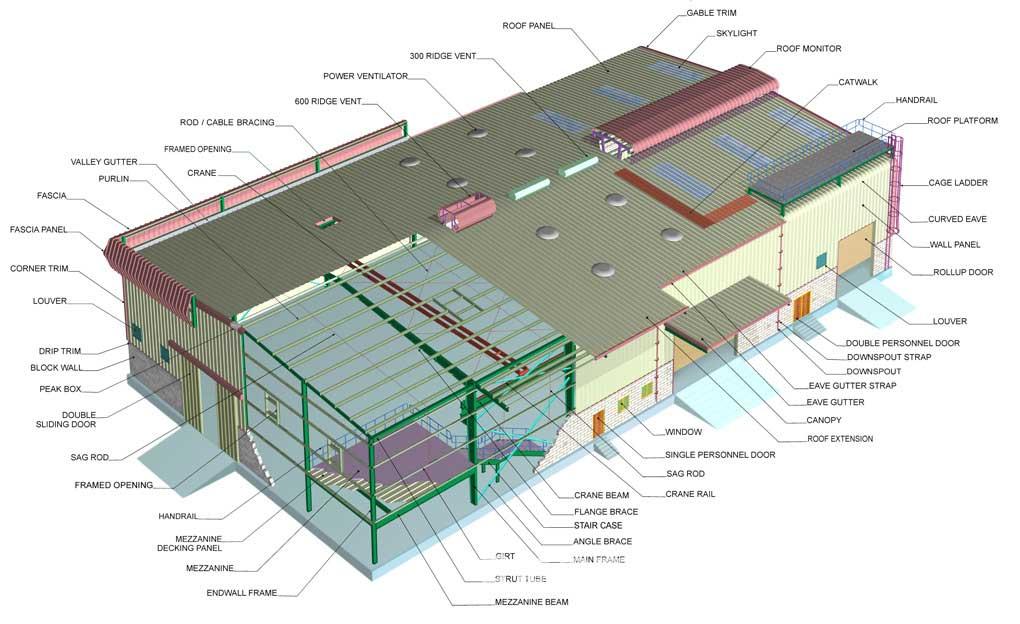

Steel structure workshop is specially built for the production of enterprises. The main components are made of steel, including steel columns, steel frames, steel beams, steel foundations and steel roofs, etc. It is a new type of building structure, suitable for industrial, commercialand agriculturalindustries. Due to the advantages of short construction time, low construction cost and low maintenance cost. It is widely used. The building has stood the test of time. It has excellent short and long term value.

Product Features

1). Clearspan, which maximizes the interior open spaces without obstructing columns and beams, it benefits industrial structures, manufacturing facilities, warehouses, plants and workshops, storages, etc.

2). Economical metal Industrial buildings have superior waterproofing, wind resistance, and anti-seismic features.

3). They are most practical, durable, flexible, and virtually maintenance-free.

4). The construction is fast and easy, all the framing components are cut, welded, drilled, and painted at the factory for quick assembly at the construction site.

5). Building a steel workshop is eco-friendly. It can reduce wastes when using prefabrication techniques. And the energy-saving designs can also improve manufacturing efficiencies.

Product Parameters

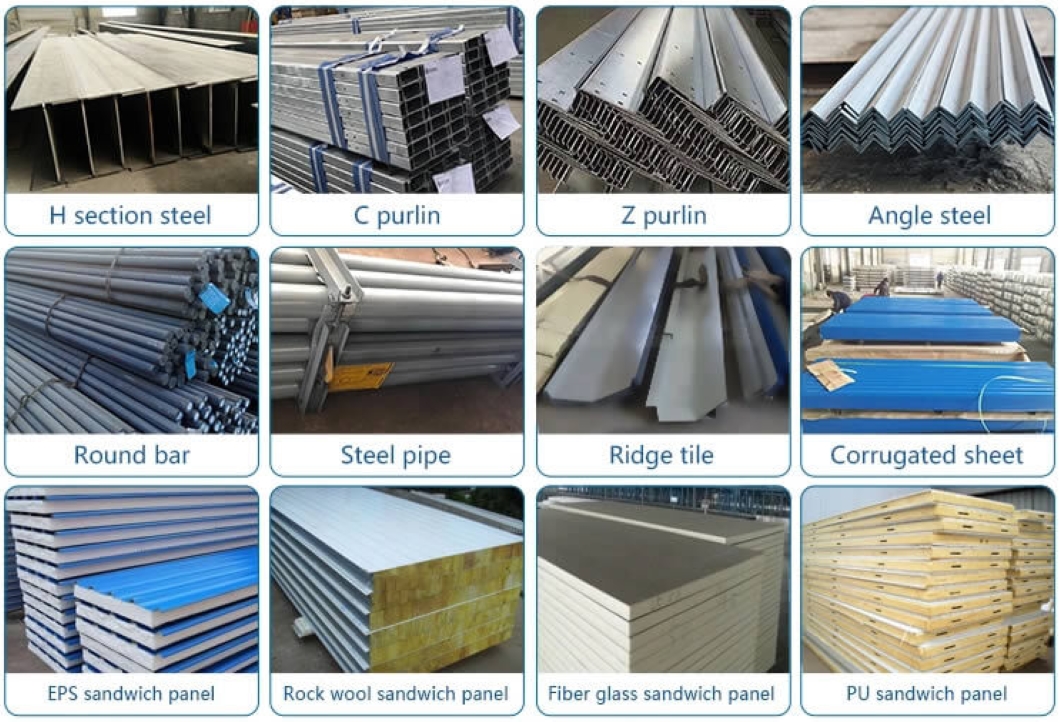

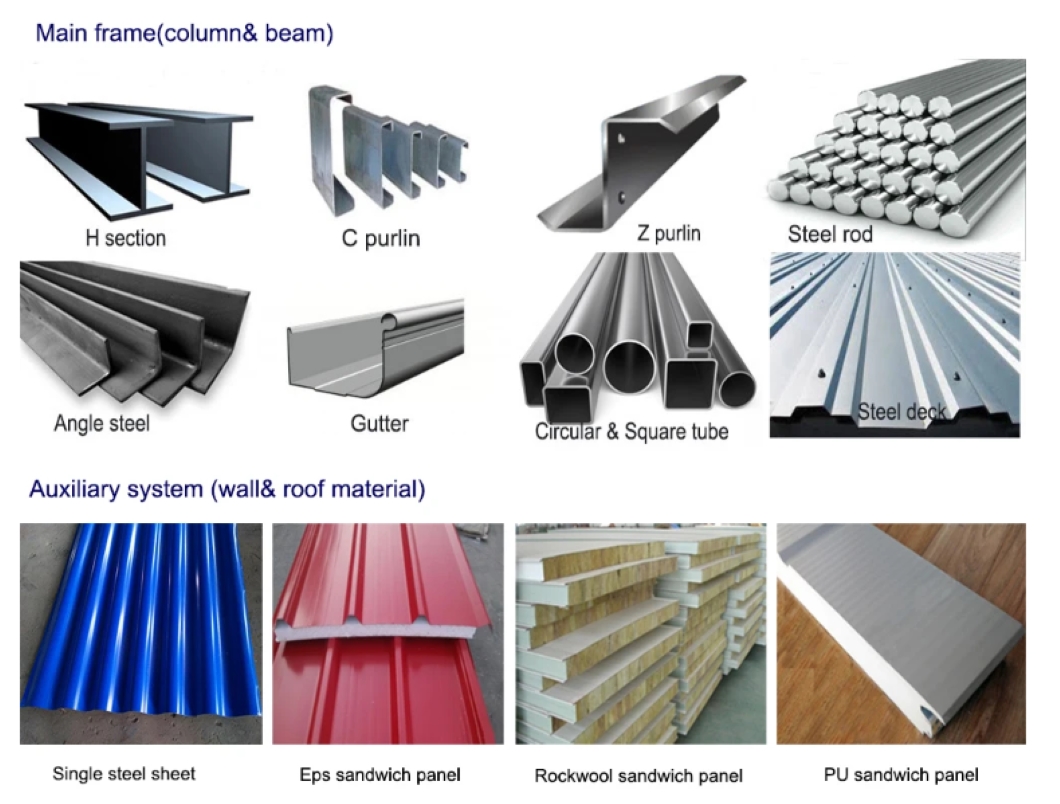

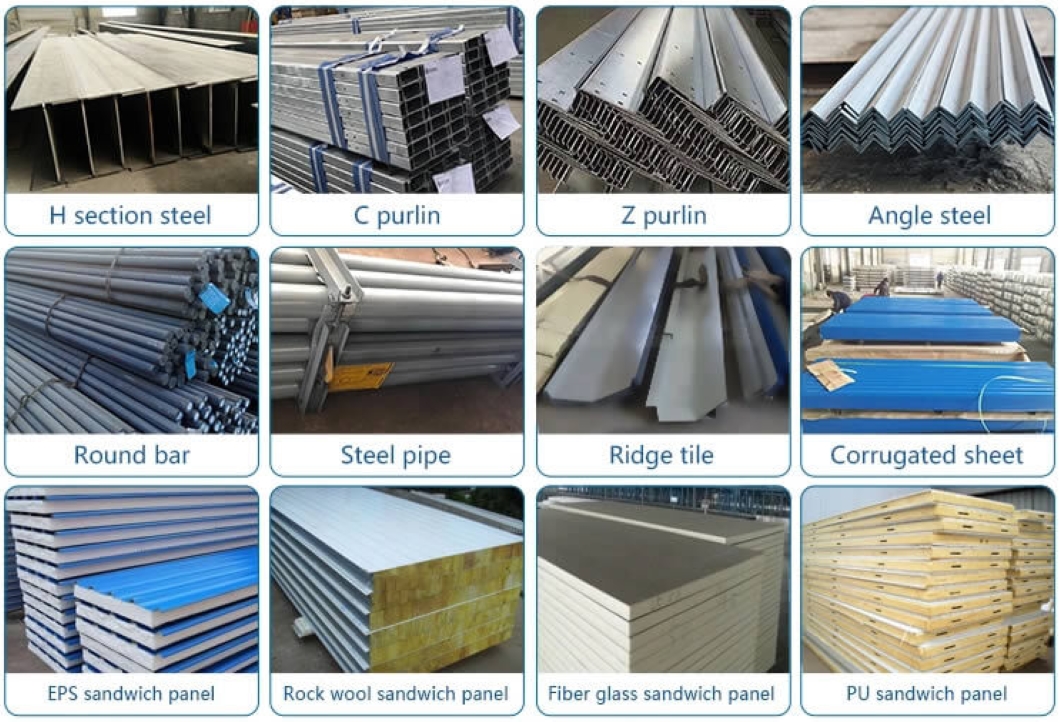

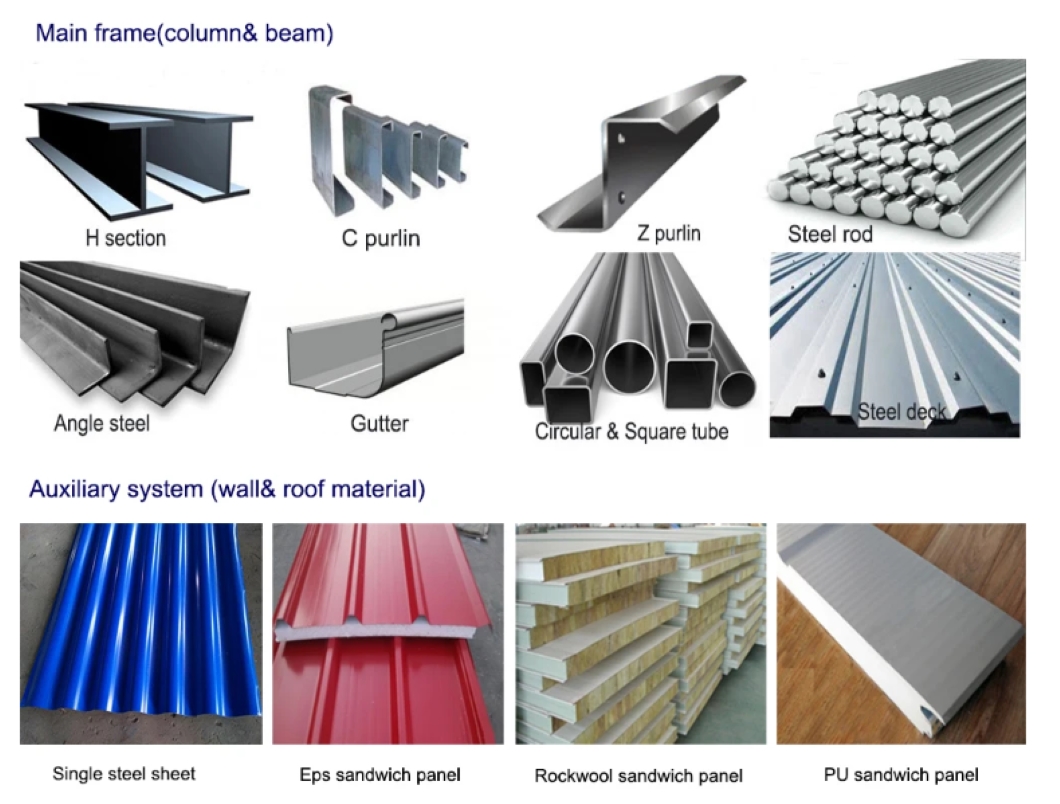

Main Steel Frame

| H section steel | Q235/Q355 grade steel 8mm/10mm |

Welding | Automatic submerged arc welding |

Rust removal | Shot blasting Sa 2.5 |

Surface processing | Alkyd painting or galvanized |

Intensive bolt | Grade 10.9 |

Sub Steel Frame

| Angle brace | L50x4, Steel Q235, processed and painted |

Cross support | Φ20, Steel Q235, processed and painted |

Tie rod | Φ89*3, Steel Q235, processed and painted |

Bracing | Φ12, Steel Q235, processed and painted |

Standard bolt | Galvanized bolt |

Roof

| Purlin | C#160,C#180,C#250, galvanized |

Roof panel | Insulated sandwich panel or corrugated steel plate |

Skylight panel | 2.0mm FRP |

Accessories | Glass cement, self-tapping screws,etc |

Flashing/Trimming | Sheet steel profile |

Gutter | Galvanized sheet steel profile |

Water pipe | Φ110 PVC |

Walls

| Purlin | C#160,C#180,C#250, galvanized |

Wall | Insulated sandwich panel or corrugated steel plate |

Accessories | Glass cement, self-tapping screws,etc |

Flashing/Trimming | Sheet steel profile |

Ventilation | Axial fan |

Doors | Rolling door/sliding door | Automatic or manual |

Windows | Sliding/fixed/shutter | Aluminum or PVC window frame |

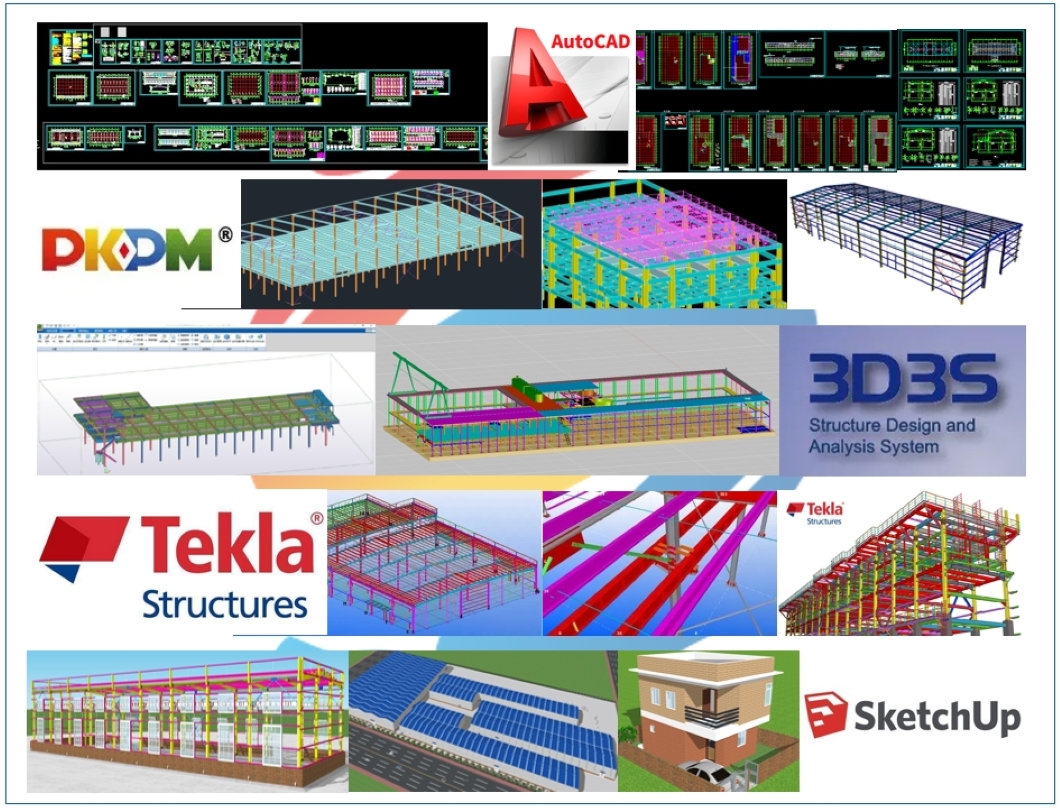

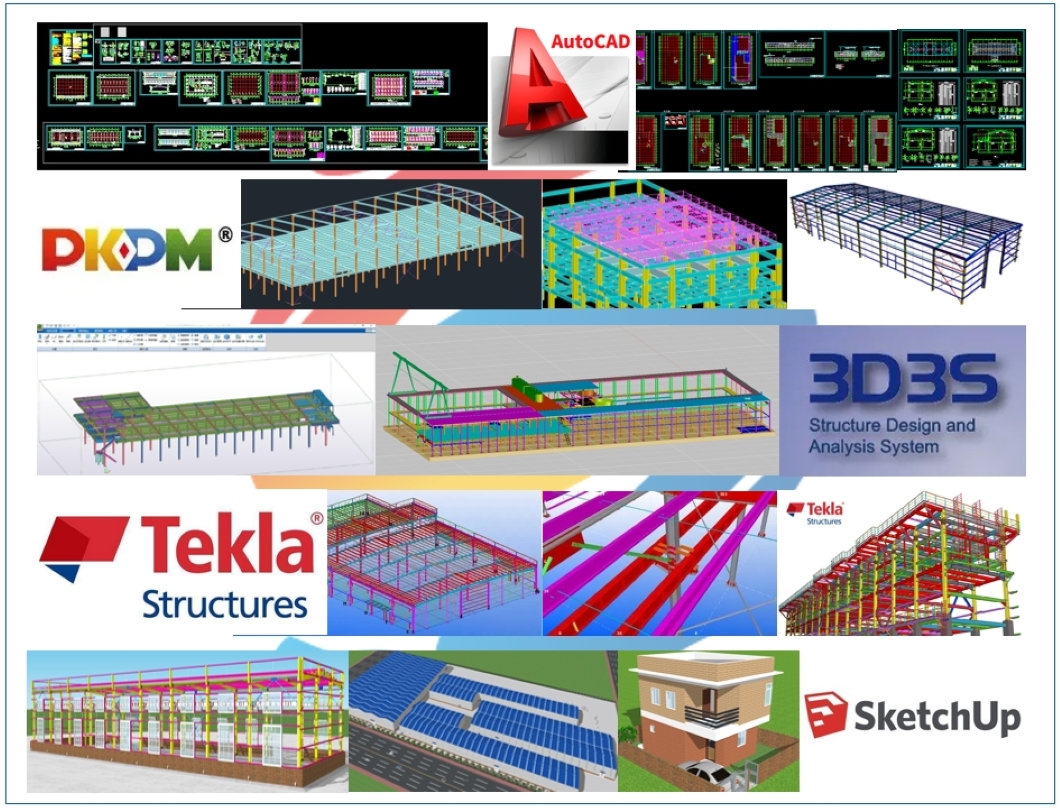

Professional design

1.We have professional design team, working experience more than 10 years;

2.We are a direct factory of steel structure building, we can design drawing according to your request.

Certifications:

QCX has the qualification certificate of overseas contracted project management issued by the Ministry of Commerce of China, CE certification [EN1090 certificate], IS09001 certificate, etc, and has long-term cooperation with countries along the " Belt and Road"