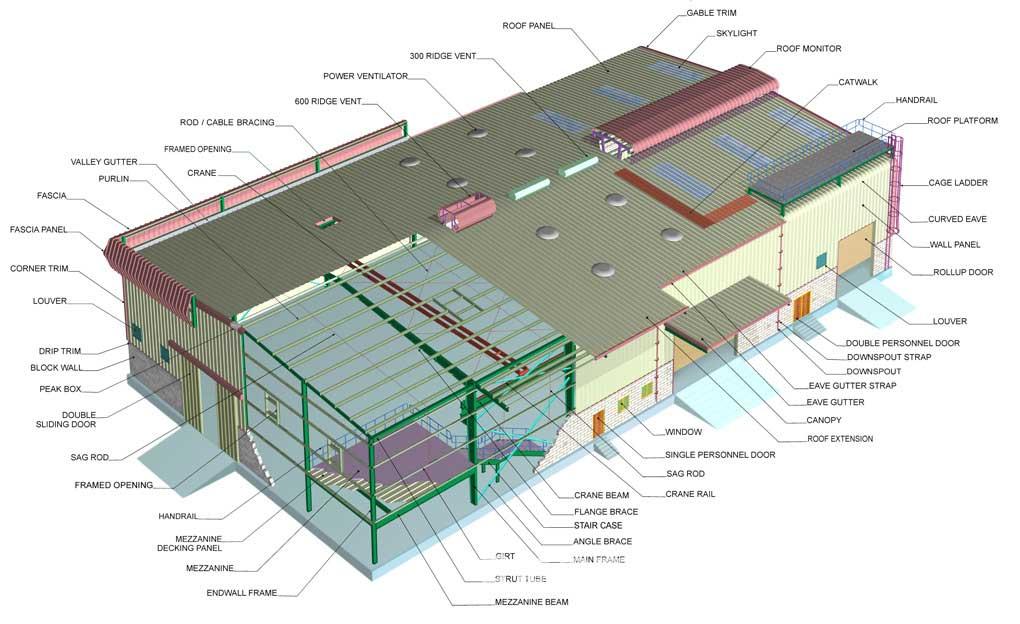

Main Steel Frame

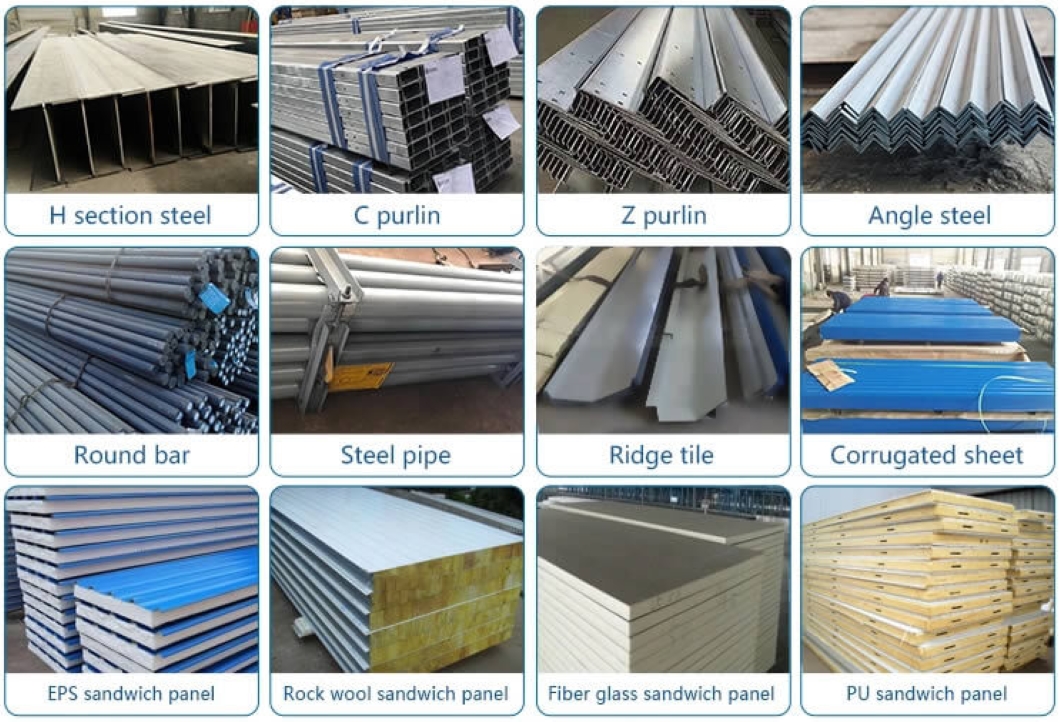

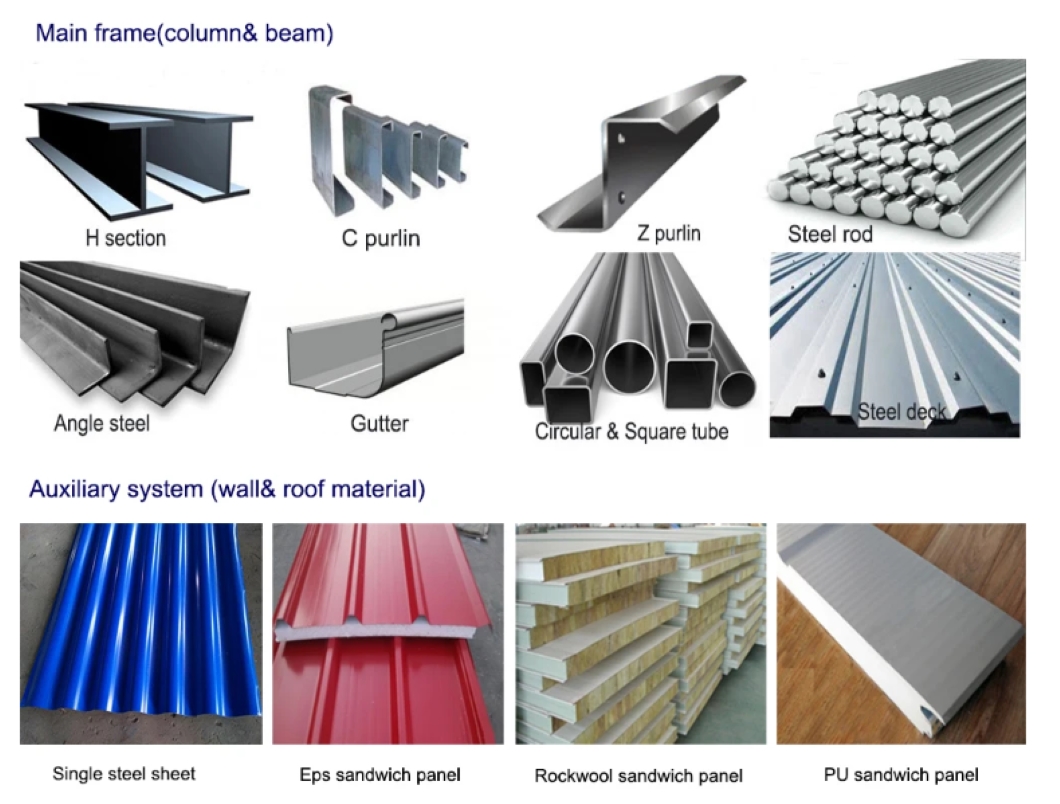

| H section steel | Q235/Q355 grade steel 8mm/10mm |

Welding | Automatic submerged arc welding |

Rust removal | Shot blasting Sa 2.5 |

Surface processing | Alkyd painting or galvanized |

Intensive bolt | Grade 10.9 |

Sub Steel Frame

| Angle brace | L50x4, Steel Q235, processed and painted |

Cross support | Φ20, Steel Q235, processed and painted |

Tie rod | Φ89*3, Steel Q235, processed and painted |

Bracing | Φ12, Steel Q235, processed and painted |

Standard bolt | Galvanized bolt |

Roof

| Purlin | C#160,C#180,C#250, galvanized |

Roof panel | Insulated sandwich panel or corrugated steel plate |

Skylight panel | 2.0mm FRP |

Accessories | Glass cement, self-tapping screws,etc |

Flashing/Trimming | Sheet steel profile |

Gutter | Galvanized sheet steel profile |

Water pipe | Φ110 PVC |

Walls

| Purlin | C#160,C#180,C#250, galvanized |

Wall | Insulated sandwich panel or corrugated steel plate |

Accessories | Glass cement, self-tapping screws,etc |

Flashing/Trimming | Sheet steel profile |

Ventilation | Axial fan |

Doors | Rolling door/sliding door | Automatic or manual |

Windows | Sliding/fixed/shutter | Aluminum or PVC window frame |